Exotec’s Skypod System – A Unique Solution Designed to Address Supply Chain Challenges

The supply chain market, like many other industries, has been experiencing tremendous volatility and dynamic market forces. These pressures are progressively pushing companies to consider advanced automation in their supply chains and warehouses. Companies face constant pressure to secure a competent and reliable workforce at market wages that enables them to remain competitive with the […] The post Exotec’s Skypod System – A Unique Solution Designed to Address Supply Chain Challenges appeared first on Logistics Viewpoints.

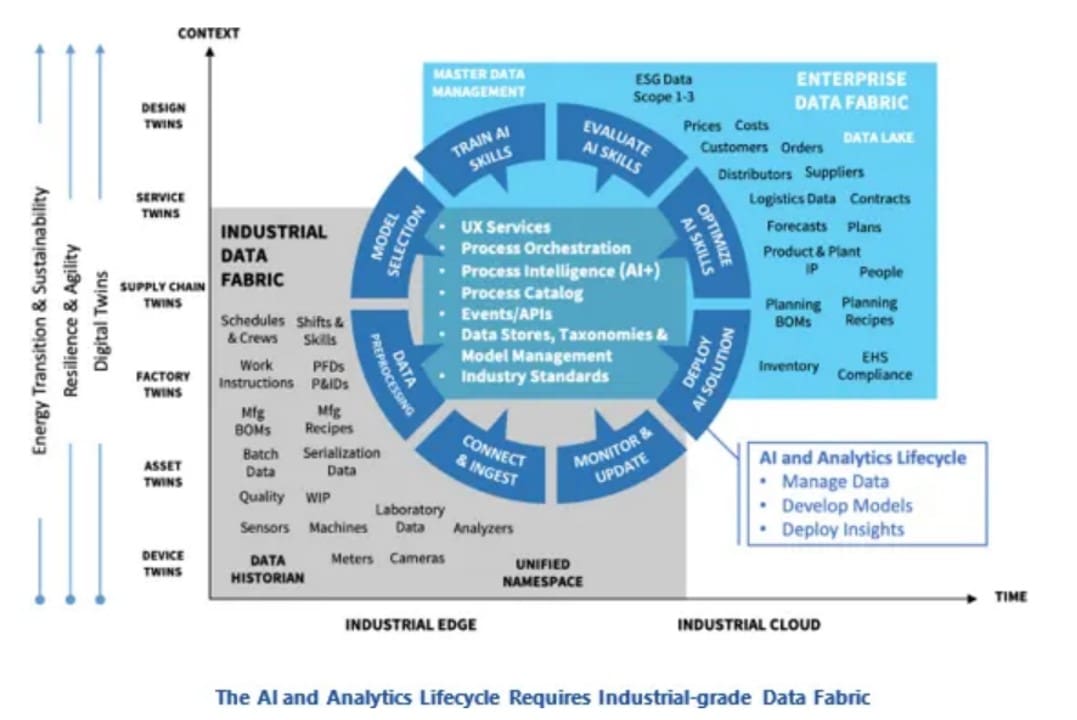

The supply chain market, like many other industries, has been experiencing tremendous volatility and dynamic market forces. These pressures are progressively pushing companies to consider advanced automation in their supply chains and warehouses. Companies face constant pressure to secure a competent and reliable workforce at market wages that enables them to remain competitive with the global market, where wages and other operating costs are often lower. In addition, many companies are facing challenges with volatile demand requirements, short lead times, an inventory comprised of hundreds of brands and thousands of SKUs, etc. Robots help warehouses deal with high turnover, don’t quit their jobs, are available 24/7, make warehouse workers more productive, and allow warehouses to scale for seasonal demands easier. This week, EXOTEC launched the next generation of its Skypod System, designed to address supply chain challenges with robotic automation.

The supply chain market, like many other industries, has been experiencing tremendous volatility and dynamic market forces. These pressures are progressively pushing companies to consider advanced automation in their supply chains and warehouses. Companies face constant pressure to secure a competent and reliable workforce at market wages that enables them to remain competitive with the global market, where wages and other operating costs are often lower. In addition, many companies are facing challenges with volatile demand requirements, short lead times, an inventory comprised of hundreds of brands and thousands of SKUs, etc. Robots help warehouses deal with high turnover, don’t quit their jobs, are available 24/7, make warehouse workers more productive, and allow warehouses to scale for seasonal demands easier. This week, EXOTEC launched the next generation of its Skypod System, designed to address supply chain challenges with robotic automation.

Many companies operating in industries such as retail, 3PLs, food and grocery, and healthcare have particularly demanding application requirements. These requirements necessitate solutions that can address the need for high throughput, warehouse storage density, and a goods-to-person system capable of handling both case and each picking. Traditionally, this has required significant investment in extra conveyors, sorters, external storage, and additional packing stations. ARC was recently briefed by Arthur Bellamy, Chief Revenue Officer at Exotec, on the Next Generation of its Skypod System, which has been in development for several years and was recently released to the public. Exotec formally launched the Next Generation of the Skypod System on February 6, 2025, and ARC participated in the launch event.

The Next Generation of the Skypod System is designed to help companies benefit from a versatile system that works with fewer conveyors, sorters, external storage, and packing stations. This not only saves money but also ensures that users benefit from a high throughput system in a small density environment. Exotec claims that new advanced software, combined with several design improvements, including a new and more compact Skypod robot, a workstation for robot-to-robot picking, a high-throughput Exchanger, and denser storage, can improve throughput at a single workstation by 50 percent while also enhancing storage density by up to 30 percent compared to the previous generation Skypod system.

The key differentiator for the Next Generation of Skypod is its ability to handle both each and case picking, positioning the firm to better address multichannel needs with a single solution. The system also natively supports several value-added logistics features that traditionally require external equipment and complex subsystems. This not only enables customers to simplify the flow of goods through the warehouse but also significantly shrinks the system footprint by reducing the need for conveyors, sorters, external storage, and packing stations. Specifically, the Next Generation of Skypod supports:

- Integrated Buffer: The Next-Gen Skypod handles buffering within the system. Following order preparation at the workstation, completed or semi-completed orders are automatically stored inside the racks until they are ready for outbound or further consolidation. This reduces the need for staging areas or other external buffer systems.

- Perfect Sequencing: The Next-Gen Skypod handles strict outbound sequencing prior to ejecting orders by using robots and the Exchanger. The robots group orders and deliver them in a specific arrangement to the Exchanger, which then routes the orders to outbound. This enables precise loading of pallets, containers, or trucks based on delivery routes, store planograms, or other unloading requirements, all without the need for external sorting equipment.

- Pick-and-Pack: The Next-Gen Skypod handles packing as an integrated part of the picking process. Operators pick directly into fulfillment containers, removing the need for manual packing operations downstream. This functionality pairs extremely well with right-size packaging solutions. These solutions can be integrated with the Next-Gen Skypod to enable picking into right-size containers, significantly cutting last-mile costs.

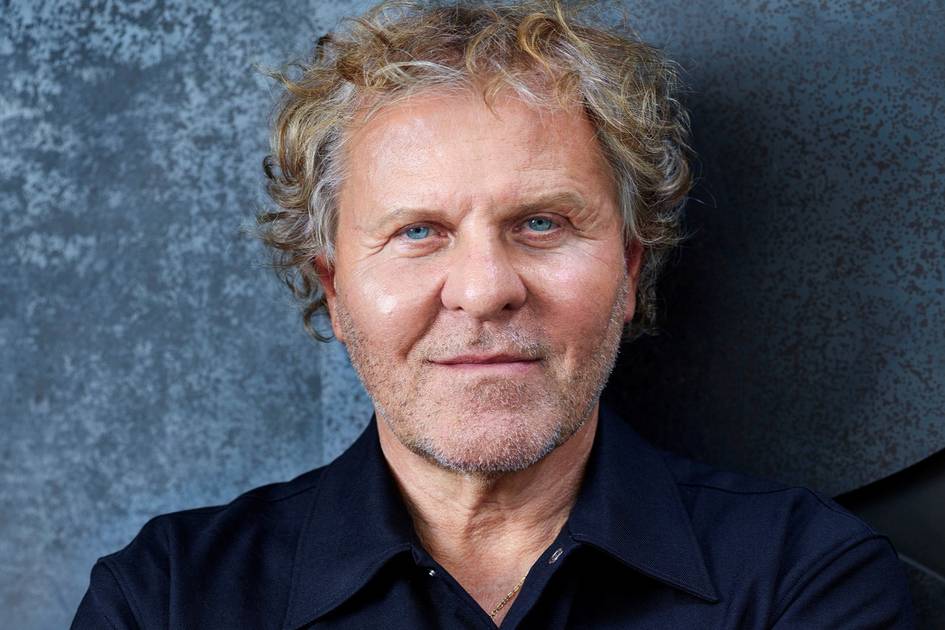

“When designing the Next Generation Skypod, our goal was to create a solution that would set the industry standard of operational excellence and elegance for the next decade and beyond,” said Romain Moulin, CEO and co-founder of Exotec. “We’re already seeing our customers reimagine their entire supply chain around the transformative capabilities of this innovation, from combining case and each picking operations to leveraging outbound sequencing to improve transportation costs. Witnessing this level of impact has been incredibly rewarding.”

Exotec developed the Next Generation of Skypod in response to evolving market needs and feedback from its existing customer base, which increasingly demands warehouse robotics to address a wider range of processes within the warehouse walls. Over the past two years, Exotec has sold and deployed the Next Generation Skypod system globally in stealth mode. The company has successfully secured over 20 projects worldwide, totaling $400M, to customers including Oxford Industries (Tommy Bahama, Lilly Pulitzer, Southern Tide, etc.), Grainger, and E.Leclerc to strengthen their supply chain operations.

ARC believes that, although less than 15 percent of all warehouses worldwide are automated to any degree, a growing number of companies will be forced to invest in automation. Solutions such as those offered by companies like Exotec will increasingly play a larger role in a growing number of industries and applications.

The post Exotec’s Skypod System – A Unique Solution Designed to Address Supply Chain Challenges appeared first on Logistics Viewpoints.