The Emergence of Supply Chain Data Fabrics

ARC was recently briefed by InterSystems. When one thinks of supply chain software vendors, the name InterSystems may not spring to mind. The company aims to change this with the expansion of its data fabric portfolio. Business cycles are compressing and the need to make course corrections is exploding. When you combine the volume, complexity, […] The post The Emergence of Supply Chain Data Fabrics appeared first on Logistics Viewpoints.

ARC was recently briefed by InterSystems. When one thinks of supply chain software vendors, the name InterSystems may not spring to mind. The company aims to change this with the expansion of its data fabric portfolio. Business cycles are compressing and the need to make course corrections is exploding. When you combine the volume, complexity, and speed with which decisions need to be made and executed, the current way companies manage this is unsustainable. Decisions need to be digitized. A supply chain data fabric can help companies augment their supply chain processes.

Who is InterSystems?

InterSystems is a rapidly growing global private company with nearly 2,000 employees and revenues of over $1 billion. The company is headquartered in Boston, Massachusetts, in the US. They offer software systems and technology for complex integration, rapid application development, and advanced analytics and sell those solutions to companies that need to accelerate optimized business outcomes. They also used these technologies to build healthcare information systems and have achieved considerable success in that industry. They aim to achieve the same success in supply chain management that they have achieved in the healthcare sector. Their premise is that the supply chain sector is ripe for a solution to improve existing supply chain planning and execution systems and processes, and could benefit from the speed, scalability, and integration capabilities InterSystems provides. The company’s flagship supply chain product is InterSystems Supply Chain Orchestrator.

The Integration Problem

The most comprehensive form of planning companies engage in is integrated business planning (IBP). IBP balances what can be produced against projected demand. Based on this, a multiple-month financial, supply chain, and capital expenditure plan is produced.

Historically, the supply chain plan that resulted from the IBP process was too static. Production plans might be locked for as long as a month, regardless of how accurate the forecast was. The original plan developed in a month-long integrated business process can quickly become irrelevant as conditions change. Executives came to understand that IBP should not constrain a company’s ability to react to what was happening in the market. A production plan from an IBP meeting should be considered a rough-cut long-term plan, merely the best estimation of what was likely, not something written in stone. Production, in the short term, needed to flex to meet new opportunities and unexpected constraints.

This realization led to a new focus on agile planning. Agile planning is short-term planning that allows companies to flex to meet market demands. COVID accelerated executives’ understanding that supply chains needed to be agile.

However, a control tower that supports longer-term integrated business planning, short-term agile planning, and execution requires complex integration.

Implementing integrated business planning was already difficult. Often the core planning is done by a supply planning solution that creates a digital map of a company’s supply chain. That supply planning application needs to be integrated into an array of internal systems – ERP, transportation management, warehouse management, procurement, and other applications. Large companies often have a heterogeneous IT environment where different regions and divisions use different ERP and supply chain applications. So, the integration surrounding supply planning is already quite complex.

However, over time, most companies have expanded their digital supply chain model from being mainly internally facing to including an array of external trading partners and participants. Those can include suppliers, contract manufacturers, logistics service providers, customs brokers, governmental agencies, and other participants. That makes the integration even more difficult.

Then, when you move from IBP to agile planning, the integration is an order of magnitude more difficult. Now companies are trying to collect data from multiple tiers of a supply chain in near real-time. Further, each product a manufacturer produces usually has different end-to-end supply chain partners.

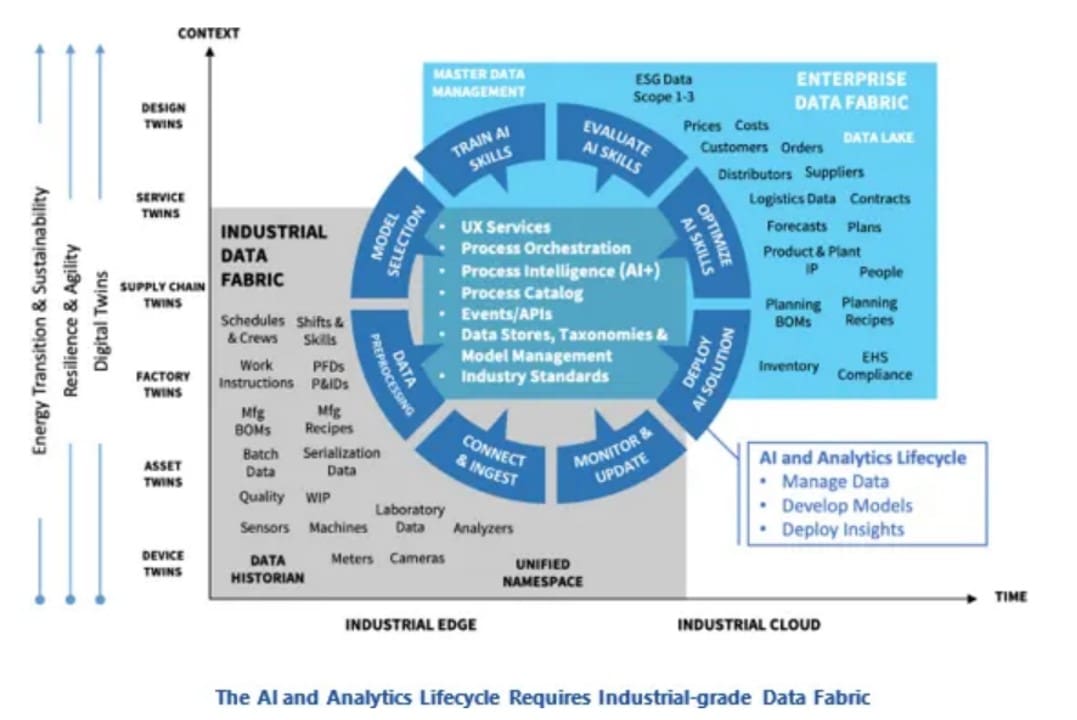

The challenges are not just about the volume but also the complexity and fragmentation of data generated by sensors, machines, and smart factories. This data is often disconnected and scattered across various applications, making it difficult to harness for insights and decision-making.

To solve this problem, data fabric technology is being increasingly used. InterSystems offers an enterprise data fabric that speeds and simplifies access to data assets across the entire business. It accesses, transforms, and harmonizes data from multiple sources to make it usable and actionable for a wide variety of business applications. They use this foundation to provide historical, predictive, and prescriptive analytics.

The Orchestration Problem

Generating integrated business plans, engaging in agile planning, and then executing those plans requires complex orchestration, near real-time visibility inside and outside the enterprise, and embedded advanced analytics to provide data driven prescriptive guidance to understand the impact and tradeoffs of various potential actions in response to unexpected exceptions and disruptions. While suppliers of enterprise applications assert that their platform supports all necessary orchestration, most companies find that is not the case, even if their whole enterprise application stack runs on one platform.

Companies need to coordinate and automate across multiple and often competing stakeholders. Those stakeholders include planners; supply chain, manufacturing, and logistics executives; sales and marketing; finance or regional or business unit leaders; and suppliers and other partners.

When a disruption occurs, and a plan cannot be created that meets all service level goals, complex tradeoffs are often required. Marketing may want an optimization scenario that costs more but leads to maximum service levels for a new product. A sales executive may argue that a very large customer needs priority because of their importance. A logistics planner may assert that expediting shipments will lead to very high shipping costs and retard their ability to meet greenhouse emission goals. It is all but impossible to program a planning engine to meet all the competing demands that arise when diverse supply chain disruptions occur. The creation of multiple scenarios, debate, and collaboration are required to evaluate these tradeoffs.

A smart data fabric supports orchestration by embedding a wide range of analytics capabilities, including Generative AI, data exploration, business intelligence, natural language processing, and machine learning directly within the fabric.

InterSystems believes their solution can help solve a variety of common supply chain problems that arise. The company has mapped out how its solution can be used to adapt to large order changes, demand sensing, and component allocation in situations where not all customers can be easily satisfied. Creating advanced agility can clearly contribute to superior business outcomes based on better adherence to service level agreements, better customer satisfaction, and lower costs.

Supply Chain Orchestrator fits well to provide an AI-enabled decision intelligence platform that predicts disruptions before they occur, and optimally handle them when they do, to be ready to manage the unexpected with confidence.

Combined with their smart data fabric architecture, it provides a real-time connective tissue to unify disparate data sources, and a set of next-generation solutions that complement your existing technology infrastructure to accelerate decision making and time to value, driving efficiencies throughout your entire supply chain.

This greatly enables Integrated Business Planning applications to accelerate their planning engine performance.

Final Thoughts

A new category of enterprise data fabrics is emerging to meet the unique needs of large businesses with complex supply chain processes. These new data fabrics must go beyond traditional enterprise data fabrics, which are not optimized for supply chain environments. These new platforms need to be able to embrace intricate supply chain data, real-time alerting, and complex decision-support tradeoffs. Such a platform is needed to allow companies to truly support agile business execution.

The post The Emergence of Supply Chain Data Fabrics appeared first on Logistics Viewpoints.