Descriptors of InZrOx vs ZnZrOx Catalysts for CO2 Hydrogenation to Methanol

Advanced Energy Materials, EarlyView.

Speciation study and benchmarking of standardized indium-zirconium (InZrO

x

) and zinc-zirconium oxide (ZnZrO

x

) materials prepared by flame spray pyrolysis enables common reactivity descriptors for CO2 hydrogenation to methanol to be classified. For both families, isolated In/Zn atoms are the optimal speciation for performance. The higher activity of isolated InZrO

x

is linked to its superior surface oxygen vacancy chemistry and hydrogen addition ability.

Abstract

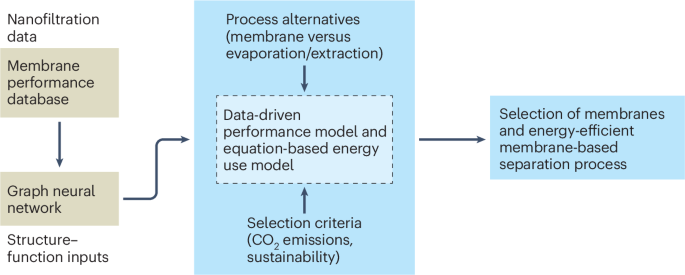

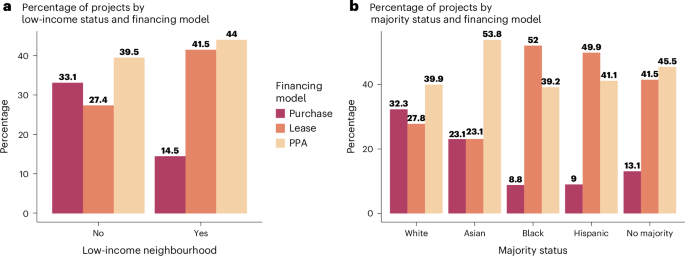

Indium-zirconium (InZrO x ) and zinc-zirconium oxides (ZnZrO x ) have emerged as highly selective and stable catalysts for CO2 hydrogenation to methanol, a versatile energy carrier. However, the disparity in synthesis methods, catalyst formulations, and structures previously studied precludes quantitative comparisons between the two families. Herein, a rigorous framework is pioneered to benchmark InZrO x and ZnZrO x materials prepared by a standardized flame spray pyrolysis synthesis platform, enabling consistently high surface areas and tunable metal speciation ranging from isolated atoms (<5 mol%) to predominantly nanoparticles (>10 mol%). Isolated indium and zinc species are commonly identified to be optimal for activity and methanol selectivity in their respective families, maximizing CO2 and H2 activation abilities. InZrO x outperforms ZnZrO x across speciations and is less structure sensitive, as deviations from atomic dispersion is less detrimental on performance for the former. Focusing on representative catalysts featuring saturation of isolated species, the higher activity of 5 mol% InZrO x over its ZnZrO x counterpart is linked to differences in surface oxygen vacancy chemistry, a lower degree of product inhibition, and more facile hydrogenation of the formate intermediate to methoxy. The identification of reactivity descriptors governing both families facilitates the development of unified guidelines in designing reducible oxide catalysts.