Lenzing sustainability report 2024: net zero goal is inching closer

The headquarters in Lenzing, Austria. Credits: Lenzing Austrian cellulose fibre producer Lenzing Group has published its 2024 annual report alongside its sustainability report, the latter for the first time in accordance with the European Sustainability Reporting Standards (ESRS). Accordingly, Lenzing has updated its climate targets in 2024 to align its commitment to climate protection with the Paris Agreement goals of limiting global warming to 1.5 degrees Celsius. The company claims to currently be “the only producer of regenerated cellulose fibres with a verified science-based net-zero target.” The following nine topics were defined as material: climate & energy, water & pollution, biodiversity & ecosystems, circular economy & resources, responsible wood sourcing, sustainable innovations & products, human rights & fair labour practices, business ethics and transparency. To achieve both its short-term and long-term science-based targets, Lenzing is currently implementing a climate action plan, which is an integral part of the corporate strategy and has been approved by the management board. In recent years, the company has invested in a photovoltaic system and a biomass power plant for its Austrian locations. Furthermore, the Group invested more than 200 million euros to modernise its production sites in China and Indonesia. The conversion measures, which included upgrading to specialty fibres capacities and reducing specific emissions, were implemented in 2023. With the commissioning of two gas turbines at its Chinese site, Lenzing achieved another milestone in 2024 by converting its energy supply from coal to natural gas. CO2 emissions The Group acknowledges that the production of dissolving wood pulp and fibres are energy-intensive processes, which present a challenge. Therefore, the company avoids fossil energy as much as possible and replaces it with renewable energy sources. Investments in state-of-the-art technologies and low-carbon manufacturing processes have helped to increase energy efficiency and reduce the company's overall greenhouse gas emissions. As a result, non-profit organisation CDP placed the company on the A List in the “Climate” category for the fourth consecutive year. Lenzing was able to reduce its specific greenhouse gas emissions by 41 percent since 2017 and is on track to achieve its science-based targets. Wastewater emissions In addition to the full commissioning of a modernised wastewater treatment plant at its Indonesian site, Lenzing also took further steps in the reporting year to implement a new wastewater treatment plant at its Grimsby site (UK). The commissioning of the plant, in which Lenzing has invested 24 million euros since 2021, is planned for 2025. Upon completion of this project, wastewater emissions at the site are expected to be reduced by up to 80 percent. Sustainable innovations Lenzing also introduced hydrophobic cellulose fibres for sustainable nonwovens, which, due to their ability to pass liquids over their surface, offer completely new product solutions for hygiene applications that previously could only be achieved by using synthetic fibres. Together with the technology start-up Exponent Envirotech, Lenzing introduced a waterless dyeing technology for regenerated cellulose fibres that reduces water and dye consumption by 95 percent and 40 percent, respectively, compared to conventional water-based dyeing processes. Textile recycling In the area of textile waste, Lenzing collaborated with leather alternatives expert Recyc Leather to launch new footwear materials made from Tencel Lyocell fibres and recycled leather fibres, which have a lower environmental impact. The “Glacial Threads: From Forests to Future Textiles” project combines glacier protection and textile recycling: Together with partners, Lenzing is currently working on processing geotextiles made from biodegradable Lenzing fibers into new textile fibres after their use. The pilot project was awarded the “Biodiversity and Water Awards at the CNMI Sustainable Fashion Awards 2024 in Milan. As part of the Cellfil project launched last year, which is co-financed by the EU with 6.9 million euros, Lenzing is working with non-profit organisation RTDS Group and 13 other partners from research and industry to promote the scaling of Lyocell filaments. Since 2021, Lenzing has also been collaborating with the Swedish pulp producer Södra to jointly develop new processes for recycling used textiles on an industrial scale. The project was supported in 2023 with a 10 million euros grant from the EU as part of the LIFE 2022 programme. The fibre producer also presented its results for the 2024 financial year.

Austrian cellulose fibre producer Lenzing Group has published its 2024 annual report alongside its sustainability report, the latter for the first time in accordance with the European Sustainability Reporting Standards (ESRS). Accordingly, Lenzing has updated its climate targets in 2024 to align its commitment to climate protection with the Paris Agreement goals of limiting global warming to 1.5 degrees Celsius. The company claims to currently be “the only producer of regenerated cellulose fibres with a verified science-based net-zero target.”

The following nine topics were defined as material: climate & energy, water & pollution, biodiversity & ecosystems, circular economy & resources, responsible wood sourcing, sustainable innovations & products, human rights & fair labour practices, business ethics and transparency.

To achieve both its short-term and long-term science-based targets, Lenzing is currently implementing a climate action plan, which is an integral part of the corporate strategy and has been approved by the management board. In recent years, the company has invested in a photovoltaic system and a biomass power plant for its Austrian locations.

Furthermore, the Group invested more than 200 million euros to modernise its production sites in China and Indonesia. The conversion measures, which included upgrading to specialty fibres capacities and reducing specific emissions, were implemented in 2023. With the commissioning of two gas turbines at its Chinese site, Lenzing achieved another milestone in 2024 by converting its energy supply from coal to natural gas.

CO2 emissions

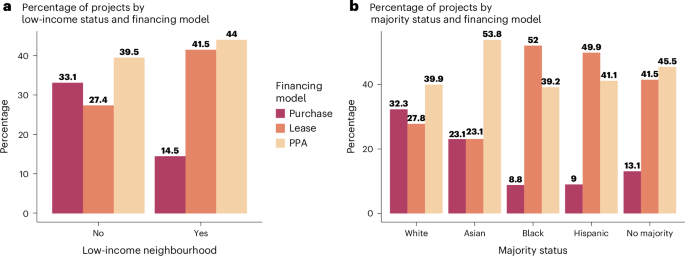

The Group acknowledges that the production of dissolving wood pulp and fibres are energy-intensive processes, which present a challenge. Therefore, the company avoids fossil energy as much as possible and replaces it with renewable energy sources. Investments in state-of-the-art technologies and low-carbon manufacturing processes have helped to increase energy efficiency and reduce the company's overall greenhouse gas emissions. As a result, non-profit organisation CDP placed the company on the A List in the “Climate” category for the fourth consecutive year.

Lenzing was able to reduce its specific greenhouse gas emissions by 41 percent since 2017 and is on track to achieve its science-based targets.

Wastewater emissions

In addition to the full commissioning of a modernised wastewater treatment plant at its Indonesian site, Lenzing also took further steps in the reporting year to implement a new wastewater treatment plant at its Grimsby site (UK). The commissioning of the plant, in which Lenzing has invested 24 million euros since 2021, is planned for 2025. Upon completion of this project, wastewater emissions at the site are expected to be reduced by up to 80 percent.

Sustainable innovations

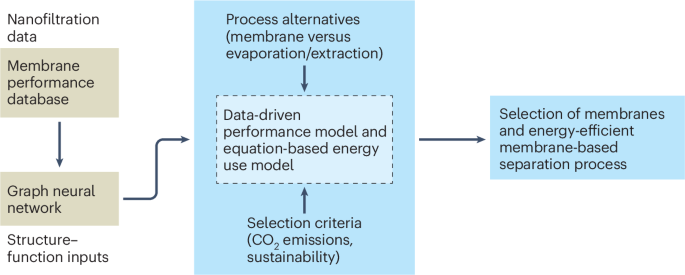

Lenzing also introduced hydrophobic cellulose fibres for sustainable nonwovens, which, due to their ability to pass liquids over their surface, offer completely new product solutions for hygiene applications that previously could only be achieved by using synthetic fibres.

Together with the technology start-up Exponent Envirotech, Lenzing introduced a waterless dyeing technology for regenerated cellulose fibres that reduces water and dye consumption by 95 percent and 40 percent, respectively, compared to conventional water-based dyeing processes.

Textile recycling

In the area of textile waste, Lenzing collaborated with leather alternatives expert Recyc Leather to launch new footwear materials made from Tencel Lyocell fibres and recycled leather fibres, which have a lower environmental impact.

The “Glacial Threads: From Forests to Future Textiles” project combines glacier protection and textile recycling: Together with partners, Lenzing is currently working on processing geotextiles made from biodegradable Lenzing fibers into new textile fibres after their use. The pilot project was awarded the “Biodiversity and Water Awards at the CNMI Sustainable Fashion Awards 2024 in Milan.

As part of the Cellfil project launched last year, which is co-financed by the EU with 6.9 million euros, Lenzing is working with non-profit organisation RTDS Group and 13 other partners from research and industry to promote the scaling of Lyocell filaments.

Since 2021, Lenzing has also been collaborating with the Swedish pulp producer Södra to jointly develop new processes for recycling used textiles on an industrial scale. The project was supported in 2023 with a 10 million euros grant from the EU as part of the LIFE 2022 programme.

The fibre producer also presented its results for the 2024 financial year.