Highly Stabilized Ni‐Rich Cathodes Enabled by Artificially Reversing Naturally‐Formed Interface

Advanced Energy Materials, Volume 15, Issue 11, March 18, 2025.

The application of Ni-rich cathode materials is obstructed by interfacial and structural instability. This work proposes a facile and cost-effective Al-based vapor-phase surface reaction strategy on Ni-rich cathode to maintain its structural integrity from near-surface to bulk. This strategy unlocks the possibilities of achieving outstanding performance for Ni-rich cathode without significantly increasing manufacturing cost.

Abstract

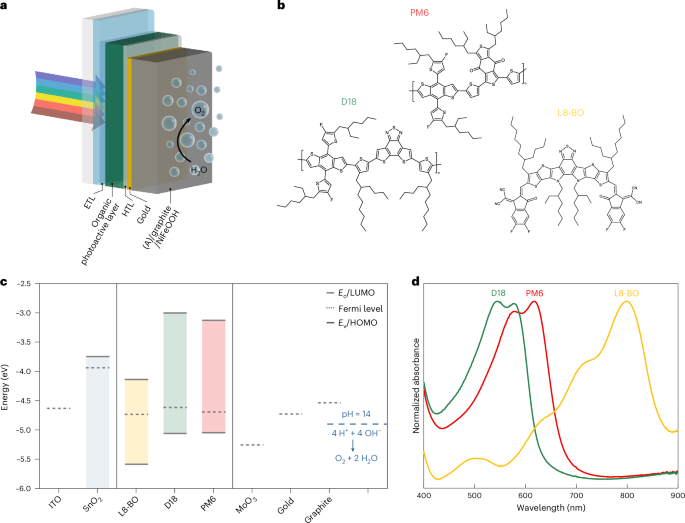

A significant obstacle in the manufacturing and practical application of Ni-rich cathode materials is decreasing the manufacturing cost without sacrificing the cycling stability. Here a high-energy, ultrahigh-Ni, and nearly Co-free cathode with outstanding cycling performance is proposed. This promising cathode is enabled by artificially constructing an “outside-in” interface structure toward LiNi0.94Co0.05Mn0.01O2 (NCM94) cathodes. Combining theoretical prediction and experimental results, it is revealed that high interfacial stability is achieved by a specific surface chemistry with an outside-in structure composed of an inner organic layer and an outer inorganic layer. Benefiting from the protection effect of the robust outside layer and the strain relieve function of the inside layer, the intrinsic challenges of interfacial reactions, transition metal (TM) dissolution, and micro-crack propagation have been mitigated for the Ni-rich cathode. As a result, the “outside-in” strategy enables superior cycling stability with a 92.7% retention after 200 cycles and an excellent rate capability of 149.1 mAh g−1 at 10 C, achieved by adding only 0.5% of the production cost. This study unlocks the possibilities of achieving outstanding performance for ultrahigh Ni cathode by spending minimum cost through the facile surface chemistry method.