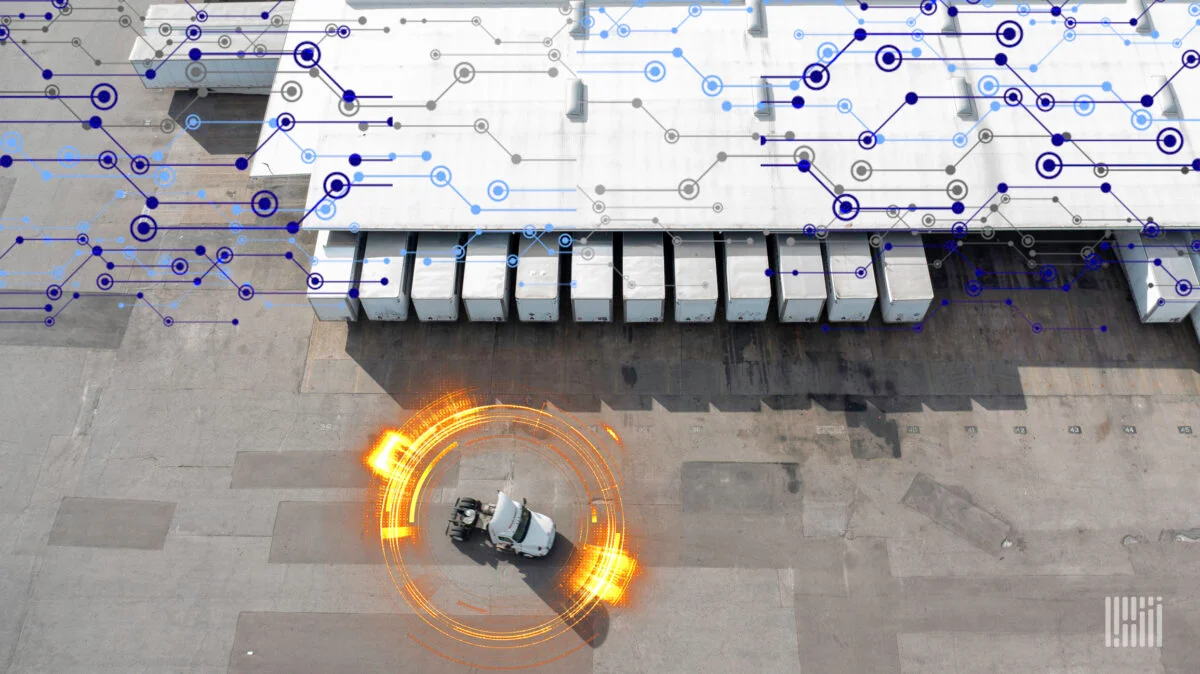

Developing Agile Procurement Strategies: Thriving Amid Global Trade Disruptions

As a supply chain executive, picture beginning your day with a cup of coffee when a news alert notifies you of newly imposed tariffs affecting your primary suppliers in China. Your inbox quickly fills with concerned emails highlighting rising costs, delayed materials, and your team’s urgent efforts to assess the situation and determine the next […] The post Developing Agile Procurement Strategies: Thriving Amid Global Trade Disruptions appeared first on Logistics Viewpoints.

As a supply chain executive, picture beginning your day with a cup of coffee when a news alert notifies you of newly imposed tariffs affecting your primary suppliers in China. Your inbox quickly fills with concerned emails highlighting rising costs, delayed materials, and your team’s urgent efforts to assess the situation and determine the next steps.

This isn’t a hypothetical scenario; it’s the daily grind for many businesses in 2025, where global trade rules shift faster than you can update your spreadsheets. Companies leaning heavily on global sourcing? They’re feeling the heat most, as sudden trade policy curveballs throw procurement plans into chaos.

Tariffs on steel from China—up 25%—and retaliatory moves from Canada and Mexico may turn supplier relationships upside down. A U.S. manufacturer I know saw their import costs jump overnight, forcing a rethink of a decade-old sourcing strategy. Traditional procurement, with its long-term contracts and rigid supplier ties, just isn’t cutting it anymore. To stay in the game, you’ve got to go agile—adaptable, proactive, and ready for whatever the trade winds blow your way.

Direct Material Procurement: Unlocking Major Cost Savings

Here’s the thing: for most companies, direct material procurement—the materials you need to actually make your products—eats up the biggest percentage of supply chain costs. Unlike indirect spending (think printer ink or coffee machines), disruptions here don’t just dent your budget; they stall production lines and compromise your ability to recognize revenue

Manage direct materials right, though, and the payoff’s huge. Picture an automotive giant renegotiating steel contracts with new suppliers across multiple regions. They may be able to shave 15% off their costs and dodge a tariff bullet. Strategic moves like bulk buying, closer supplier partnerships, and syncing procurement with supply chain planning can tighten inventory, cut waste, and free up cash. It’s not just about pinching pennies—it’s about ensuring business continuity.

What Is Agile Procurement?

Agile procurement is your lifeline. It’s not about locking in decade-long deals or crossing your fingers that suppliers stay stable. It’s flexible, fast, and built to roll with the punches—using real-time smarts to dodge risks and grab opportunities.

Let’s break it down with some examples that hit home:

Supplier Diversification: Reflecting on the disruptions caused by the pandemic, companies heavily reliant on Chinese suppliers faced significant challenges. In contrast, Apple demonstrated foresight by relocating portions of its iPhone production to Vietnam and India. This strategic shift enabled the company to mitigate the adverse effects of escalating trade tensions effectively.

Scenario Planning: Effective planning mirrors the strategic foresight required in chess, necessitating consideration of multiple future steps. An automotive company I collaborated with conducted detailed modeling of potential tariff impacts on semiconductor supply chains. Consequently, when shortages emerged, they had already secured alternative sources, thereby averting a significant disruption to production.

Technology Integration: The adoption of artificial intelligence has proven transformative in supply chain management. A Fortune 500 retailer, for instance, reduced its procurement cycle time by 30% by leveraging an AI-driven tool to analyze supplier data efficiently.

Cross-Functional Collaboration: Success in procurement requires integrated efforts beyond a single department. A consumer goods company aligned its procurement and logistics teams, resulting in a 15% reduction in working capital.

Sustainability Focus: Increasing consumer emphasis on sustainability has elevated its importance in supply chain decisions. A prominent retailer incorporated environmental, social, and governance (ESG) criteria into its supplier selection process, enhancing its reputation and ensuring compliance with regulatory standards.

Figure 1: Key Differences Between Traditional and Agile Procurement

| Aspect | Traditional Procurement | Agile Procurement |

|---|---|---|

| Contract Structure | Long-term, locked-in contracts | Flexible deals that bend with the market. |

| Supplier Base | Single supplier | Diverse sources |

| Approach | Reactive | Proactive |

| Technology Use | Tech-light | AI-driven |

Strategies for Implementing Agile Procurement

To effectively develop an agile procurement strategy, organizations should focus on the following key initiatives:

1. Supplier Diversification

Depending too heavily on a single supplier or region exposes businesses to unnecessary risks. Companies should expand their supplier base, identifying alternative sources in different geographic regions. For example, China+1 strategies, where companies retain some suppliers in China but also establish relationships in Vietnam, India, or Mexico, can provide flexibility in the face of shifting tariffs.

2. Scenario-Based Planning

Companies must conduct what-if analyses to understand the impact of different tariff scenarios and global trade shifts. By leveraging integrated scenario planning (ISP) tools, procurement teams can model potential disruptions and develop contingency plans in advance.

3. Nearshoring and Local Sourcing

Given the unpredictability of global trade policies, nearshoring has become a viable option. Businesses that source materials and components from regional suppliers can benefit from reduced lead times, lower logistics costs, and minimized tariff exposure. For example, U.S.-based manufacturers shifting sourcing to Mexico instead of Asia traditionally took advantage of USMCA trade benefits while maintaining supply chain agility. With the new tariffs on Mexico, it may be prudent for companies to explore building factories within the USA.

4. Contract Flexibility and Dynamic Pricing Models

Long-term fixed-price contracts may not be suitable in volatile markets. Instead, companies should negotiate flexible contracts with key suppliers, incorporating dynamic pricing mechanisms that adjust based on market conditions, currency fluctuations, and tariff changes.

5. AI-Driven Procurement Optimization

Advanced procurement technologies powered by AI and machine learning can enhance supplier selection, cost forecasting, and risk assessment. AI tools can analyze vast amounts of data to recommend optimal supplier matches, predict price trends, and identify potential supply chain disruptions before they occur.

Conclusion: Thriving in a Volatile Trade Environment

In today’s dynamic trade landscape, procurement leaders must shift from reactive problem-solving to proactive strategy execution. Agile procurement enables companies to remain competitive by anticipating market shifts, mitigating risks, and optimizing costs. By diversifying suppliers, leveraging scenario planning, integrating technology, and embracing adaptive supply chain principles, businesses can navigate trade disruptions with confidence. Companies that fail to adopt agile procurement risk higher costs, reduced profitability, and supply chain fragility. On the other hand, those that invest in agility will not only survive but thrive in an unpredictable global economy.

by Nari Viswanathan – Sr. Director, Product Segment Marketing, Coupa

Nari is currently Sr. Director of Product Segment Marketing at Coupa, where he brings products to markets in the areas of Direct Material Procurement and Supply Chain Design and Planning. Over the past 20 years, Nari has held VP and Director of Product Management, Research and Marketing roles at Aberdeen Group, River Logic, Steelwedge and E2open. He has significant experience building products from the ground up and managing the P&L for a product suite. He is a proven B2B marketer with expertise in content marketing, competitive intelligence, and positioning. He has published numerous thought leadership articles, whitepapers, blogs and delivered dozens of webinars during his career. Nari Viswanathan is a six times SDCExec Supply Chain Pro to Know award winner. Nari holds a master’s degree in Manufacturing Systems Engineering at the University of Wisconsin-Madison and a bachelor’s degree in Mechanical Engineering at the Indian Institute of Technology, Chennai.

The post Developing Agile Procurement Strategies: Thriving Amid Global Trade Disruptions appeared first on Logistics Viewpoints.

.jpg)