Solvent Engineering for Scalable and Sustainable Fabrication of Lead‐tin Perovskite Solar Cells

Advanced Energy Materials, EarlyView.

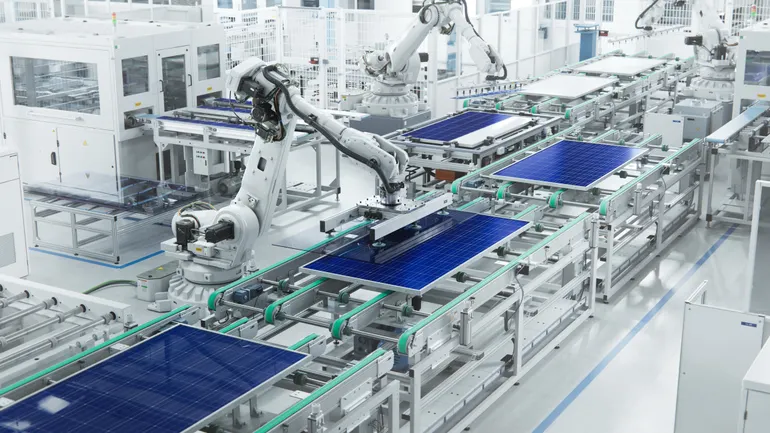

Scaling up Pb-Sn PSCs from the laboratory to an industrial scale requires addressing challenges related to scalable preparation technologies and solvent sustainability. This work introduces two innovative, low-toxic solvent mixtures for a two-step blade-coating deposition process of the active perovskite layer, resulting in efficient and stable Pb-Sn perovskite devices.

Abstract

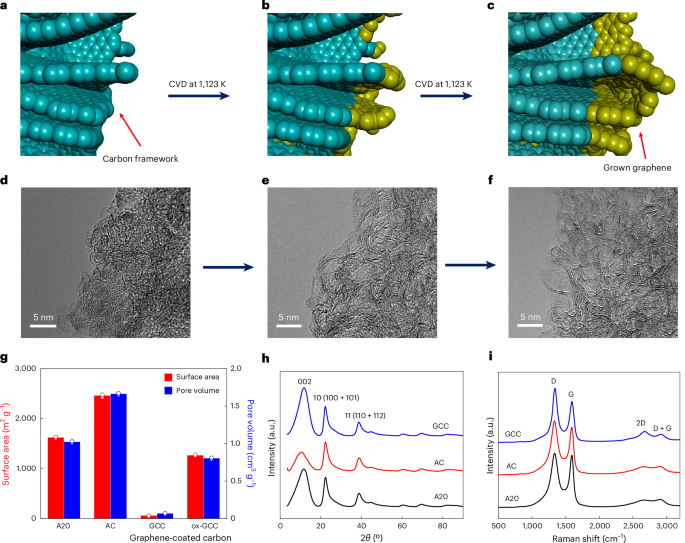

Hybrid lead-tin (Pb-Sn) perovskites have emerged as a promising avenue for photovoltaic technology with reduced toxicity and optimized bandgap. However, scaling up Pb-Sn perovskite solar cells (PSCs) from laboratory to industrial scale involves tackling challenges associated with scalable preparation technologies and the sustainability of solvents, the latter representing by far the major component of the reactant mixture(s). Here, innovative low-toxic solvent mixtures are proposed for a two-step blade-coating deposition process of the active perovskite layer: initially, diethylformamide (DEF) and dimethylsulfoxide (DMSO) (in 9:1 volume ratio), for processing the inorganic components of hybrid Pb-Sn perovskites (first step); then, in a second step, isopropanol (IPA) and 2-methyl-2-butanol (2M2B) (in 3:2 volume ratio) for the organic components, promoting the diffusion of the organic cation and the full precursor conversion to perovskite. Employing this low-toxic solvent engineering, low-D/3D Pb-Sn perovskites are successfully prepared with a champion power conversion efficiency (PCE) of 14.2%. Additionally, the devices prepared with both solvent systems retain more than 90% of their initial PCE after storage under an inert atmosphere for ≈2 months. This study represents a significant step toward understanding industrial viability, where not only efficiency but also sustainability of the production process should be considered.