Revolutionising pallet wrapping

At Carlton Packaging, we’re committed to delivering innovative, sustainable packaging solutions that redefine efficiency for fulfilment operations across the globe. Our wrapX® system is the ultimate answer to modern pallet wrapping — a complete solution designed to enhance operational speed, reduce plastic usage and improve workplace safety. The System: Engineered for Performance The wrapX® system [...] The post Revolutionising pallet wrapping first appeared on Warehouse & Logistics News.

At Carlton Packaging, we’re committed to delivering innovative, sustainable packaging solutions that redefine efficiency for fulfilment operations across the globe. Our wrapX® system is the ultimate answer to modern pallet wrapping — a complete solution designed to enhance operational speed, reduce plastic usage and improve workplace safety.

The System: Engineered for Performance

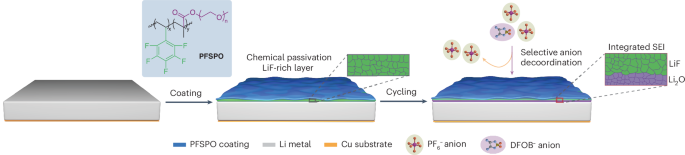

The wrapX® system combines ergonomic design with cutting-edge technology to streamline your entire wrapping process. At its core is the unique 2-1-2 wrapping technique: two wraps at the base, one in the middle, and two at the top. This method enhances load stability while using significantly less film, delivering consistent, high-tension application with minimal waste.

Through a thoughtful, operator-first design, wrapX® reduces bending, stretching and repetitive strain. Workers can now safely walk forward while wrapping, increasing visibility and safety on the warehouse floor. It’s a smarter, safer way to wrap — empowering fulfilment teams to enhance performance without compromising wellbeing.

The Dispenser: Carbon Fibre, Lightweight. Ergonomic.

The wrapX500 dispenser is constructed from ultra-lightweight carbon fibre, offering maximum manoeuvrability with minimal effort. Designed with comfort and control in mind, it features a low-profile frame, an ergonomic grip and an adjustable tension control mechanism, allowing for smooth, consistent wrap application, every time.

Innovative features such as magnetic docking make the dispenser easy to store and access at packing stations, racking or forklifts. A core locator enables faster roll changes, while the floor stand protects rolls when not in use. It’s the perfect blend of efficiency and ergonomic design, engineered to meet the demands of high-volume warehouse environments.

The Film: Smarter Material for a Greener Future

The exclusive wrapX® ELITE film is a high-performance, nano-layer stretch wrap with up to 80% stretch and 30% recycled content, exempting users from plastic packaging tax in the UK. Available in multiple grades to suit your specific requirements, the film delivers up to 60% less usage per pallet compared to conventional alternatives.

Whether you’re looking to save time, reduce plastic or maximise yield, wrapX® film provides increased load stability and minimal environmental impact. Thanks to its consistent high-tension application, you get fewer revolutions per pallet, faster wrapping times and lower logistics costs, all while supporting your sustainability goals.

The Tower: Reach New Heights

For operations that require wrapping taller pallets, the wrapX® Tower is the ideal extension. Designed with a longer handle for increased reach, it maintains the same ergonomic benefits as the standard dispenser while improving access to high loads. This enhancement reduces operator strain and ensures every pallet is wrapped consistently.

About Carlton Packaging

Carlton are leading designers and suppliers of dispatch packaging for fulfilment operations globally. With over three decades of experience, Carlton have shaped a reputation as one of the most knowledgeable and forward-thinking packaging solutions providers worldwide. Committed to delivering sustainable, efficient and intelligent packaging solutions, Carlton continues to develop cutting-edge technologies that drive operational efficiency, cost reduction and environmental responsibility.

Ready to wrap smarter?

Visit carltonpackaging.com, email us at sales@carltonpackaging.com, or speak to one of our packaging experts for a demonstration.

Experience how wrapX® is changing the game — one pallet at a time.

The post Revolutionising pallet wrapping first appeared on Warehouse & Logistics News.