Navy contractor KEEL to spend $70M on new facilities for submarine fabrication

“We’re purpose building KEEL to help solve the capacity challenges in nuclear Navy shipbuilding,” KEEL’s Chief Executive Brian Carter told Breaking Defense.

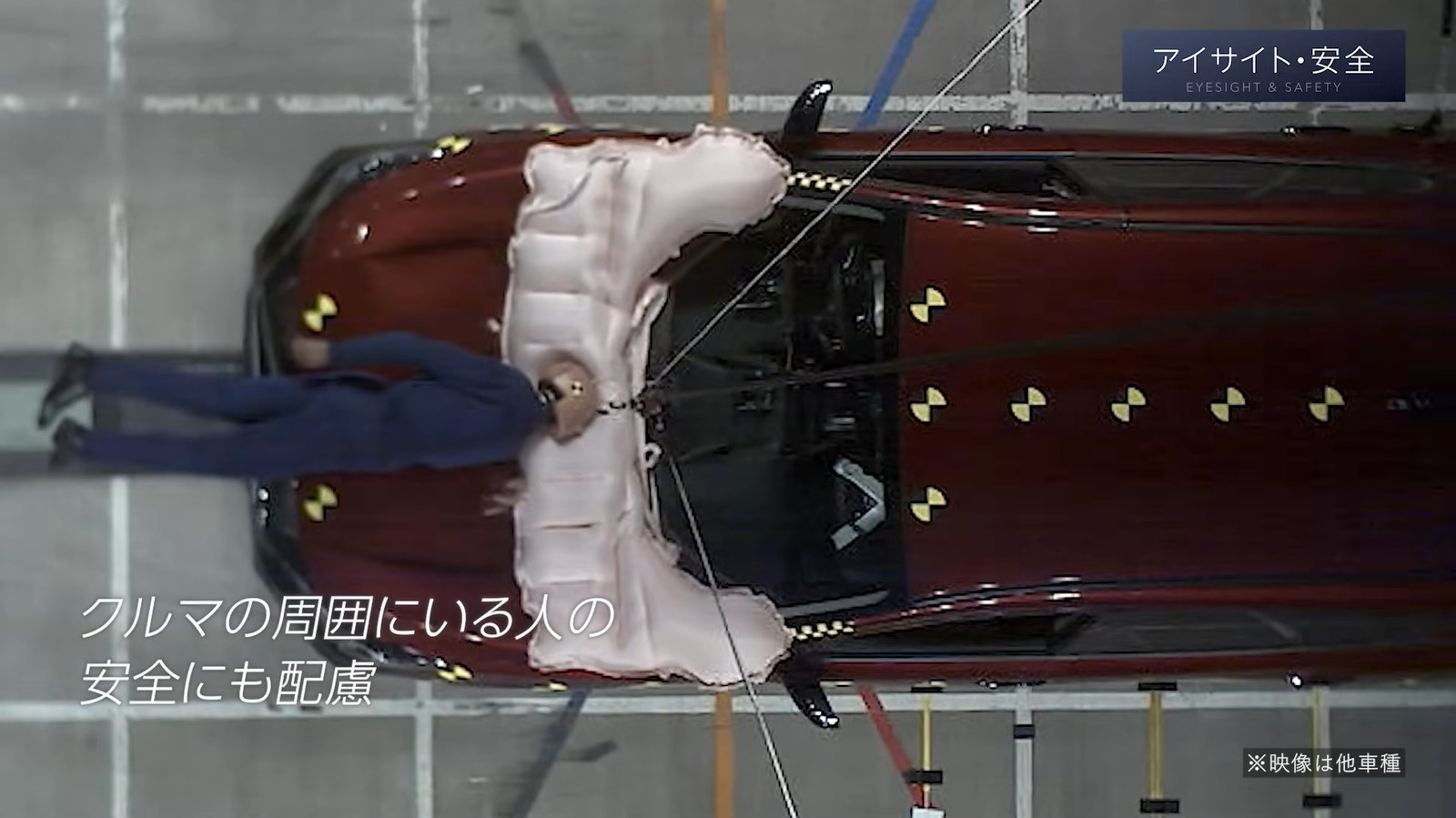

Metal Trades’ Yonges Isand facility in South Carolina. (Photo courtesy of KEEL)

WASHINGTON — South Carolina-based Navy contractor KEEL is planning to invest $70 million in three new facilities totaling 60,000 square feet focused on submarine and aircraft carrier component manufacturing in Charleston, the company’s chief executive told Breaking Defense.

“We’re purpose building KEEL to help solve the capacity challenges in nuclear Navy shipbuilding,” said Brian Carter. “This is a critical step in us adding capacity to the industry that will directly impact the and improve the schedule for building both Virginia [and] Columbia [class submarines] and future” aircraft carriers.

The company, which took its current shape in January 2024, was formed through a merger of two South Carolina companies — fabricator Pegasus Steel and shipyard Metal Trades — along with the Michigan-based Merrill Technologies Group.

Its current work for the Navy is focused on building the Columbia-class submarine superstructures that are ultimately delivered — by truck or barge — to prime contractors General Dynamics Electric Boat and HII Newport News. KEEL also fabricates numerous components to be used on future Ford-class aircraft carriers.

Carter said the expansion will include three facilities that will all start construction in 2025 or 2026 and be completed by or in 2027: a preparation and paint building; a facility for Columbia-class superstructure fabrication; and a building for employees.

KEEL’s announcement comes on the heels of numerous other Navy contractors announcing expansions in the region. HII earlier this year closed on its acquisition of metal fabricator W International. Meanwhile, Leonardo DRS last week also announced a facilities expansion in South Carolina focused on manufacturing space for naval propulsion technologies.

Carter said South Carolina’s proximity from HII and General Dynamics Electric Boat is likely a key factor in why numerous other Navy contractors are opening up shop in the region.

“It’s critical that it’s an easy voyage, if you will, for both truckable and bargeable components to both Newport News and Electric Boat,” he said. “But it’s far enough away where it’s a different labor market, and we can tap into some really great infrastructure here for training and developing our trades workforce.

“If you look at the growth of Charleston last 10-15, years, it is becoming more of a manufacturing hub, and there is quite a population growth that’s occurred along with that,” Carter continued. “And so it … should grow into more of its own shipbuilding ecosystem, if you will, to support these priority Navy programs.”