Locus Robotics Uses Simulation as a Differentiator

Before a potential customer buys an autonomous mobile robot solution, Locus Robotics often uses different types of simulation to determine the type of robots needed and the number needed to optimize productivity at a warehouse. This allows Locus to make a robust calculation of the ROI that will result from the project. This capability can […] The post Locus Robotics Uses Simulation as a Differentiator appeared first on Logistics Viewpoints.

Before a potential customer buys an autonomous mobile robot solution, Locus Robotics often uses different types of simulation to determine the type of robots needed and the number needed to optimize productivity at a warehouse. This allows Locus to make a robust calculation of the ROI that will result from the project. This capability can also be used with existing customers whose pick volumes are changing to see whether adding new bots makes sense. Locus’s simulation capabilities are a key differentiator for the company in the AMR market.

Simulation is a Critical Part of Locus Robotics’ Differentiation

Locus Robotics is a provider of autonomous mobile robots. AMRs are employed in warehouses to increase productivity and employee satisfaction. These solutions also speed up employee onboarding. As opposed to traditional automation, AMRs are a flexible form of automation that allows a warehouse to scale in a manner that does not disrupt operations.

Locus is one of the largest providers in the market – in a press release last year, they announced that their bots had completed over 4 billion picks.

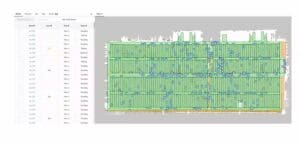

One of the key approaches to simulating warehouse operations is based on employing discrete event simulation (DES) techniques and tools. DES allows the modeling of complex warehouse operations at various levels of detail. Building a detailed DES model may be a time-intensive activity, but it pays dividends in bringing insights into the operations of a warehouse. Typically, modeling is done by highly trained engineers with an industrial engineering background. Some very large manufacturers and logistics service providers have the capability to use these tools. Most companies don’t.

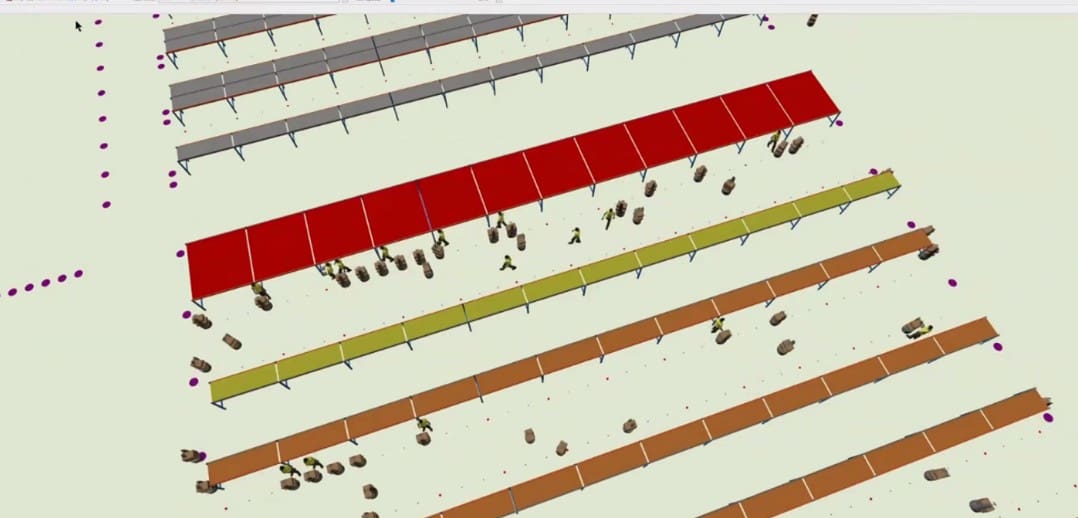

Locus Robotics employs a multi-faceted approach to simulating the warehouse operations of a fleet of autonomous robots that combines DES techniques with detailed robot autonomy models for a highly enriched and accurate simulation of AMR warehouse operations. This is a unique capability in the industry. It allows Locus Robotics simulations to be extremely accurate.

Modeling AMRs is Complex

I interviewed Hamid Montazeri, a senior vice president of software engineering, robotics, data science & AI/ML at Locus Robotics. “Simulation,” Mr. Montazeri explained, “is an approximate representation of how a physical system works in the real world. It provides opportunities to do things that would be expensive or very time-consuming to do manually. It helps designers create a more effective system. Locus uses simulation to help design better robots and help customers learn how to optimally use Locus bots in their operations.

The more granular the simulation model, the higher the fidelity of the output. Mr. Montazeri believes simulation is a differentiator for Locus Robotics because other discrete event simulation solutions – DES is the primary form of simulation used to model warehouses and factories – poorly model how humans and mobile bots collaborate.

Modeling collaborative AMRs is more complex than modeling manual warehouses or warehouses with bolted-down material handling systems.

DES starts with a model of the warehouse – where the aisles are and how long they are. Where the shelves are, how high they are, how many pick locations are in that aisle, and so forth. Then, cyber orders are downloaded. These order lines are associated with the pick locations. Then, constraints are added. For example, these virtual pickers work in zones and don’t go outside those zones. Orders are dropped into the simulation engine, and the closest worker to a pick location is often assigned to the pick.

But with Locus, bots move to a pick location, and a worker goes to the bot and picks onto it. Then, the worker may be asked to move ten feet down an aisle where another robot is waiting. The worker goes to that bot and picks onto it. This optimization logic is designed to reduce pickers’ travel times while ensuring the orders will be packed and ready to ship on schedule. The model must incorporate this complex orchestration of virtual man and machine based on understanding how the Locus System optimizes task allocation.

Further, the Locus solution optimizes the size of the cartons used on a bot. This affects how many cartons the robot carries. This logic also needs to be understood.

Locus Robotics is not a provider of warehouse management systems. However, their simulation model must also understand how the warehouse management system creates tasks. For example, in addition to assigning workers to picks, the WMS may print labels at print stations that need to be attached to cases.

But Mr. Montazeri believes that the detailed simulation at the lower levels – the levels that describe how the actual machines operate – is key to the fidelity of their simulation models.

For example, it is not as simple as saying that a bot moves this fast on average. Bots have collision-avoidance logic. Avoiding a collision adds time. But how much time? The robot sensors have a specific range. The range of those sensors affects how the bot avoids collisions. This cyber-physical knowledge is incorporated into the Locus model.

Locus also has different types of robots. One of their robots can connect to a cart and then move it to a desired location. The time it takes to do this, and its navigation constraints are modeled. The company offers solutions for each picking, case picking, putaway, and moving carts. The platform also can support handoffs to conveyors, slides, and putwalls. All of this can be modeled in detail.

Further, AMR operations require communication networks. These communication networks are not perfect. Locus is unique in its ability to model imperfections and perturbances in the available communication network pathways. Bots navigate based on simultaneous localization and mapping. An understanding of how SLAM works adds additional constraints.

In short, because Locus engineers can add many aspects of the AMR autonomy stack to the simulation models, they can model the physical layer at a depth no one else can.

In a warehouse with multiple forms of automation, Locus can combine the detailed simulation models of their robots with more traditional models that can be built for other automation solutions. This provides for a more holistic simulation of warehouse operations.

Finally, Locus has sites with hundreds of robots. Almost no other vendor does. That scale adds further complexities to the modeling of warehouse operations due to congestion, collision avoidance, and understanding how bots need to queue up at various service stations.

In conclusion, for Locus Robotics, simulation is a critical tool for helping customers get the most value out of these systems and providing the value they promised.

The post Locus Robotics Uses Simulation as a Differentiator appeared first on Logistics Viewpoints.

.jpg)