Lighter, cheaper, better: Why Lucid is "doing it all" to improve EVs

Lucid’s co-founder was in on the ground floor of the EV era, and he’s still driven by a passion to innovate Peter Rawlinson, winner of Autocar’s 2025 Sturmey Award for innovation, is one of a small, distinguished crop of British engineers who have honed their skills working in challenging automotive careers at home, then risen to stellar status by taking charge of globally significant projects in other countries. Although the serious car electrification era is barely two decades old, Rawlinson is already well established as one of its principal players. He was the inspiration – ‘chief engineer’ sounds too staid – first the Tesla Model S and then the Lucid Air, arguably the two most influential EVs of the past 20 years. The Tesla, launched in 2012, is the first electric car to have achieved genuine global sales success. It did this by basing its appeal on progressive design and practical capability, and, most important of all, pioneering the use of energy-dense lithium-ion batteries. The Lucid Air is the Model S’s spiritual successor a dozen years on, offering new forms of EV efficiency that cut dramatically its dependence on fat, heavy and expensive batteries. The Air is the first of a planned range of Lucid models, the most significant of which is scheduled to be a Volkswagen Golf-sized design, two years away, that will combine affordability with long range. Rawlinson says he recently signed off the major elements of this potential winner but won’t now be leading from the front; he was recently replaced as CEO but continues to advise the creative teams he built. Rawlinson was brought up in South Wales, where he demonstrated his engineering skills early on by designing his own toys, which his handyman father made at home. He describes himself as “a country bumpkin”, but nevertheless he headed fearlessly into central London and Imperial College for his education in engineering. He says this experience, plus the arrival of a 1938 Ford 8 inherited from a departed uncle, decided the course of his life: he admits to an intense interest in cars “from which I have never looked back”. At Jaguar in his early thirties, Rawlinson took responsibility for advanced body design and crashworthiness, working on the XJ41 and XJ42 coupé and convertible projects and acquiring a helpful grounding in digital engineering. Impetuously, he left Jaguar to start his own kit car company, making Imola cars that didn’t sell but which had the virtue of using folded stainless steel for a monocoque chassis design that both influenced the Lotus Elise’s extruded aluminium chassis and encouraged Hethel to offer its inventor a job working alongside Lotus greats such as John Miles and Roger Becker. A Lotus Engineering consultancy job sent Rawlinson to California where he “got to know people” while working on an aluminium spaceframe for J Mays, soon to be boss of Ford Design. Along the way, he also designed the Th!nk electric city car for Norwegian clients, using the battery compartment to provide extra chassis rigidity in a way that would later stand him in good stead. A friend, Adrian van Hooydonk, now BMW’s design chief, put Rawlinson in contact with Elon Musk, then a billionaire rocketry enthusiast with a passion to build electric cars. Franz von Holzhausen, an American who had worked for Mazda and GM, was already working on the Model S’s long-nosed shape, which was to prove less than perfect for the first Tesla. Still, it looked great. Rawlinson credits Musk with inspiring him to make EVs. “At the time, even scientists said the energy density of batteries was so poor, nothing could be done,” he says. “But Elon said we were going to use lithium-ion batteries, the kind they put in laptops. This promised cars that could do 200 miles with 70kWh of batteries, weighing 300kg. It was a game-changer. We’d spotted the fact that EVs were viable, and no one knew! This was my chance. Elon wanted to rethink everything. I knew I was the right guy to do that, so I grabbed it with both hands.” The Model S, as we all now know, became a hit. Nearly 300,000 units have been built since June 2012, from a two million Tesla total, and production continues. Even so, Rawlinson admits that the baked-in faults of the Tesla Model S made room for his second game-changer, the Lucid Air, currently made in California by a company he co-founded after a falling-out with Musk. Rawlinson says one Model S drawback is that it was styled before its mechanical layout was designed; a second foible is that insufficient original thinking was applied to its powertrain. For the Lucid Air, a more efficient motor was integrated with the rest of the powertrain, which has been a significant boost. The clue for the future, insists Rawlinson, is reducing battery cost and size while delivering the top-end range and performance that is a Lucid speciality. “I co-founded Lucid not just to make EVs but to advance the art of electric cars,” he says. “Using smaller batteries is absolutely cru

Lucid’s co-founder was in on the ground floor of the EV era, and he’s still driven by a passion to innovate

Lucid’s co-founder was in on the ground floor of the EV era, and he’s still driven by a passion to innovate

Peter Rawlinson, winner of Autocar’s 2025 Sturmey Award for innovation, is one of a small, distinguished crop of British engineers who have honed their skills working in challenging automotive careers at home, then risen to stellar status by taking charge of globally significant projects in other countries.

Although the serious car electrification era is barely two decades old, Rawlinson is already well established as one of its principal players. He was the inspiration – ‘chief engineer’ sounds too staid – first the Tesla Model S and then the Lucid Air, arguably the two most influential EVs of the past 20 years.

The Tesla, launched in 2012, is the first electric car to have achieved genuine global sales success. It did this by basing its appeal on progressive design and practical capability, and, most important of all, pioneering the use of energy-dense lithium-ion batteries.

The Lucid Air is the Model S’s spiritual successor a dozen years on, offering new forms of EV efficiency that cut dramatically its dependence on fat, heavy and expensive batteries.

The Air is the first of a planned range of Lucid models, the most significant of which is scheduled to be a Volkswagen Golf-sized design, two years away, that will combine affordability with long range.

Rawlinson says he recently signed off the major elements of this potential winner but won’t now be leading from the front; he was recently replaced as CEO but continues to advise the creative teams he built.

Rawlinson was brought up in South Wales, where he demonstrated his engineering skills early on by designing his own toys, which his handyman father made at home. He describes himself as “a country bumpkin”, but nevertheless he headed fearlessly into central London and Imperial College for his education in engineering.

He says this experience, plus the arrival of a 1938 Ford 8 inherited from a departed uncle, decided the course of his life: he admits to an intense interest in cars “from which I have never looked back”.

At Jaguar in his early thirties, Rawlinson took responsibility for advanced body design and crashworthiness, working on the XJ41 and XJ42 coupé and convertible projects and acquiring a helpful grounding in digital engineering.

Impetuously, he left Jaguar to start his own kit car company, making Imola cars that didn’t sell but which had the virtue of using folded stainless steel for a monocoque chassis design that both influenced the Lotus Elise’s extruded aluminium chassis and encouraged Hethel to offer its inventor a job working alongside Lotus greats such as John Miles and Roger Becker.

A Lotus Engineering consultancy job sent Rawlinson to California where he “got to know people” while working on an aluminium spaceframe for J Mays, soon to be boss of Ford Design. Along the way, he also designed the Th!nk electric city car for Norwegian clients, using the battery compartment to provide extra chassis rigidity in a way that would later stand him in good stead.

A friend, Adrian van Hooydonk, now BMW’s design chief, put Rawlinson in contact with Elon Musk, then a billionaire rocketry enthusiast with a passion to build electric cars. Franz von Holzhausen, an American who had worked for Mazda and GM, was already working on the Model S’s long-nosed shape, which was to prove less than perfect for the first Tesla.

Still, it looked great. Rawlinson credits Musk with inspiring him to make EVs. “At the time, even scientists said the energy density of batteries was so poor, nothing could be done,” he says.

“But Elon said we were going to use lithium-ion batteries, the kind they put in laptops. This promised cars that could do 200 miles with 70kWh of batteries, weighing 300kg. It was a game-changer. We’d spotted the fact that EVs were viable, and no one knew! This was my chance. Elon wanted to rethink everything. I knew I was the right guy to do that, so I grabbed it with both hands.”

The Model S, as we all now know, became a hit. Nearly 300,000 units have been built since June 2012, from a two million Tesla total, and production continues.

Even so, Rawlinson admits that the baked-in faults of the Tesla Model S made room for his second game-changer, the Lucid Air, currently made in California by a company he co-founded after a falling-out with Musk.

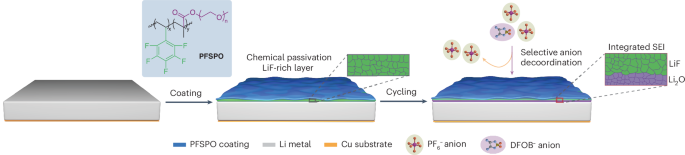

Rawlinson says one Model S drawback is that it was styled before its mechanical layout was designed; a second foible is that insufficient original thinking was applied to its powertrain. For the Lucid Air, a more efficient motor was integrated with the rest of the powertrain, which has been a significant boost.

The clue for the future, insists Rawlinson, is reducing battery cost and size while delivering the top-end range and performance that is a Lucid speciality. “I co-founded Lucid not just to make EVs but to advance the art of electric cars,” he says. “Using smaller batteries is absolutely crucial to that.

“Some people believe the real task is to make batteries cheaper, but even if you achieve that, the weight and size won’t change and you’ll probably have less output. The real task is to make cars go farther with less battery – by saving weight, improving aerodynamics and cutting frontal area, by cooling batteries better and making motors more efficient. We’re doing all of it. That’s the vision of Lucid.”