In-line CT Delivers Real-time Quality Feedback on the Production Line

German luxury automaker BMW uses CT scanning for engine housings of every single one of its advanced iX model EVs. The post In-line CT Delivers Real-time Quality Feedback on the Production Line appeared first on Fabricating & Metalworking.

As the complexity of modern vehicles has risen dramatically in recent decades, particularly in the case of electric ones (EVs), the value of pre-assembly quality checks at key stages during active production has become increasingly apparent. In addition to various methods of surface scanning, some of the leading automotive manufacturers (along with others in aerospace, energy and electronics) are using computed tomography (CT) to inspect deep inside complex components to ensure they are fit to send to the assembly line.

Now, CT scanning is expensive. But so is only finding out that costly components are defective after a vehicle rolls off the assembly line. The savings achieved in time and resources when valuable automotive parts are inspected for quality before they are installed in a vehicle can be significant.

That’s what German luxury automaker BMW has concluded—which is why they are CT scanning the engine housings of every single one of their advanced iX model EVs.

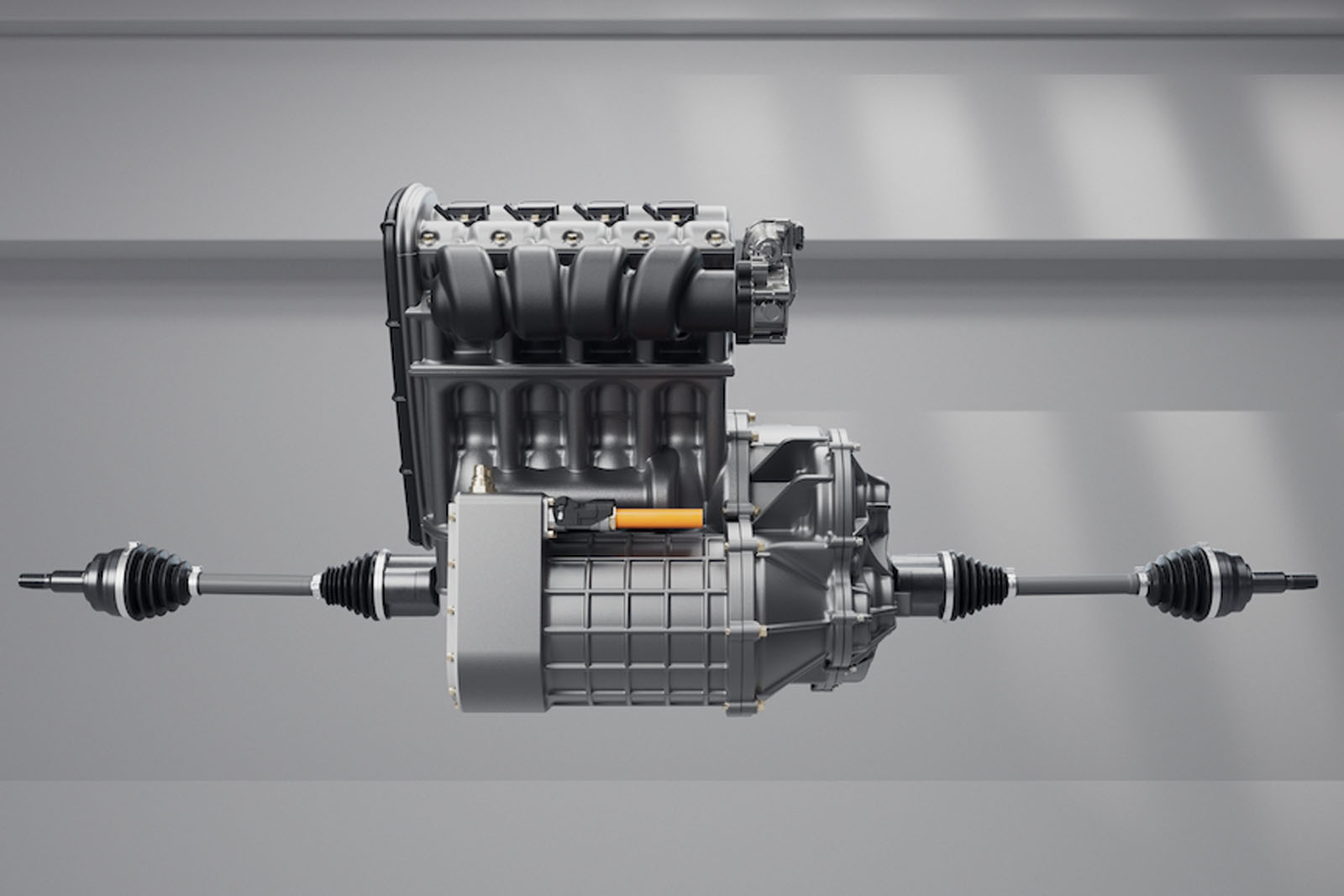

In contrast to the company’s other current electric vehicles, the iX is based on an independent platform. But it uses the same drive unit (motor, inverter, transmission) known as HEAT (Highly-Integrated Electric Drive Train) that is employed in the other BMW models. Ensuring the consistency and quality of this valuable drivetrain is clearly a priority for the automaker.

Robots and scanners and software—on the line

At its Landshut, Germany, facility, BMW is using a combination of in-line robotics, CT scanning and detection, and analysis and visualization software, to inspect their HEAT e-engine housing during active production. The entire system was installed and integrated into their production line by Heitec, a global engineering solutions provider for a broad range of industries.

Heitec’s installation delivers a continuous-flow process in which a robot plucks an aluminum housing off the production line, deposits it on a platform that feeds it into a HeiDetect Inline CT scanner, then shifts to the other side of the scanner to retrieve an already-scanned component and move that one back to the line. Each scan takes place in 50 seconds.

https://www.youtube.com/watch?v=0yjRk5o7ORg

The post In-line CT Delivers Real-time Quality Feedback on the Production Line appeared first on Fabricating & Metalworking.