The Food Manufacturing Leader’s Guide to AI: Proven ROI Strategies and Implementation Roadmaps

Key takeaways: Focus on quick wins first: Start your AI journey with predictive maintenance and quality control applications, which offer the fastest returns and clearest business value, before expanding to […]

Key takeaways:

- Focus on quick wins first: Start your AI journey with predictive maintenance and quality control applications, which offer the fastest returns and clearest business value, before expanding to more complex supply chain and generative AI uses.

- Build the foundation before scaling: Invest in data quality, infrastructure, and employee training upfront — successful AI implementations depend more on having clean data and organizational readiness than on the technology itself.

- Move decisively or risk irrelevance: The competitive landscape is shifting rapidly as AI adoption accelerates across food manufacturing, making early action essential to avoid falling permanently behind industry leaders.

Is AI worth the hype or can it wait?

For food industry leaders looking to get ahead, the short answer is you can’t afford to miss out on the transformative potential of AI-driven technologies.

“Historically, the manufacturing industry has been slow to innovate,” says Tyler Marshall, who heads strategic alliances and business development at Advantive. “But with growing external pressures such as economic uncertainty and workforce challenges, manufacturers now have to modernize quickly, and AI plays a key role in this transformation.”

This quick guide provides food manufacturing leaders with concrete evidence of AI’s impact, proven implementation strategies, and actionable roadmaps for successful adoption. Whether you’re evaluating your first AI pilot or scaling existing initiatives, the insights and case studies presented here will help you navigate this transformative technology landscape with confidence.

Looking for a boardroom-ready AI playbook? Check out our AI in Food Manufacturing report.

The business case: Why AI matters now

Consumer demands for quality, safety, and sustainability are rising while margins remain under pressure. Labor shortages, supply chain volatility, and regulatory requirements add further complexity to an already challenging environment.

Against this backdrop, 50% of food companies are planning AI investments in 2025, driven by clear business imperatives: improving production efficiency (51%), enabling data-driven decision-making (47%), and achieving cost savings (45%).

The market opportunity is substantial. The AI food market is projected to grow from $9.68 billion in 2024 to $48.99 billion by 2029, while the global AI in food processing market is expected to reach $22.3 billion by 2032, growing at a CAGR of 8.3%.

And food and beverage companies echo this prediction. More than a third of the manufacturers we surveyed for our recent report on digital transformation said AI and machine learning will be the most impactful food manufacturing technology over the next three years. And 23% said AI / machine learning has delivered the biggest ROI for their operations over the past 12 months.

But perhaps most compelling is the competitive imperative. As one industry expert warns, “If, in three or four years’ time, you’re only just popping your head out of the hole, you’re going to be so far behind that it could be detrimental to your business. People need to be at least paying attention to the fact that this is something that’s happening now.”

Proven AI applications: Where companies are seeing real returns

Predictive maintenance is a quick win

For many food manufacturers, predictive maintenance represents the highest-impact, fastest-return AI application. The numbers speak for themselves:

- According to McKinsey & Company, predictive maintenance can decrease machine downtime by 30 to 50% and increase equipment lifespan by 20 to 40%, while improving Health, Safety, and Environment (HSE) standards and overall equipment uptime.

- Thanks to their adoption of AI-powered predictive maintenance, one food and beverage manufacturer achieved a 20% improvement in machine uptime across their production line while significantly reducing emergency repairs and spare part usage.

End-to-end value creation with supply chain optimization

Supply chain AI applications are delivering some of the most impressive returns in food manufacturing, particularly when implemented as integrated systems rather than point solutions.

- Unilever has developed an advanced AI-driven customer connectivity model that is revolutionizing planning, forecasting, and replenishment processes. This partnership has already delivered above 98% on-shelf availability, driving strong category growth in less than a year and reducing inventory. The system is being rolled out across 30 key customers globally.

- Beyond inventory optimization, Unilever estimates that enabling entire planning chain teams to avoid manual and ad hoc forecasting changes could reduce human effort by 30%. Distribution center and store inventory has been optimized with fewer trucks on the road, delivering precisely the required amount of stock at the right times.

- Early adopters of AI-enabled supply chain management have reduced logistics costs by 15%, improved inventory levels by 35%, and enhanced service levels by 65%.

- A coffee chain achieved significant operational improvements, including a 15% reduction in inventory levels and a 5% increase in labor productivity through AI-powered demand forecasting that enabled them to adapt to market demands more dynamically while maintaining fresher stock and avoiding overstocking or shortages.

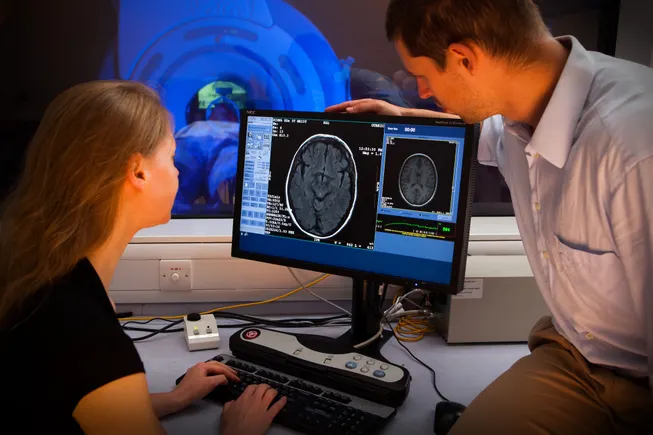

Precision at scale with quality control and inspection

Computer vision and AI-powered inspection systems are transforming quality control from a bottleneck into a competitive advantage.

- A manufacturer of automobile parts in Japan reduced labor costs by 30% and achieved a 95% defect detection rate using a visual inspection AI system, while a packaging manufacturer reported a 50% reduction in inspection time and a 10% reduction in labor costs after implementation.

- One leading manufacturer posted an 80% drop in labor costs through automatic defect classification solutions, primarily from streamlining workflows. The same solution helped a chip maker reduce reliance on workers to review images of defects, a costly and slow process that required 12 inspectors working in shifts around the clock.

- AI platforms can be designed to understand the vast variability of food products, enabling grading and sorting that identifies size, shape, color, and surface quality of food items on fast-moving production lines. The system can guide robotics to remove foreign objects and damaged items while ensuring consistent quality standards.

- Unlike traditional machine vision systems that struggle with natural variability in food products, AI-powered systems learn and adapt to acceptable variations while detecting genuine defects with unprecedented accuracy.

Keep up with market shifts with generative AI

Companies are beginning to explore generative AI for recipe development, personalized nutrition, and supply chain scenario planning. Mars, Nestlé, and other major brands are already using generative AI platforms to validate new product ideas and generate market research reports.

Sustainability and compliance: AI as an enabler

AI not only improves operational efficiency — it supports priorities like regulatory compliance and sustainability initiatives.

“AI tends to be the most valued when it replaces manual-driven processes on the shop floor,” Marshall notes. “For instance, a majority of manufacturers today still use paper and pen on the shop floor, later transferring pertinent information to Excel spreadsheets and then manually processing it for process improvement. AI will come into play as companies become more successful at capturing that info and machine data to help them make decisions faster.”

AI systems can enhance compliance with food safety regulations while reducing the burden of manual documentation and monitoring. AI-enabled systems provide comprehensive tracking from farm to fork, supporting the FDA Food Traceability Rule compliance and rapid response to food safety incidents. Meanwhile, automated inspection and documentation systems ensure consistent compliance with safety standards while reducing human error.

Automation is also revolutionizing sustainability in the food industry. By reducing waste, improving resource efficiency, and enabling smart packaging, it aligns with consumer demands for eco-friendly practices. AI-powered systems can optimize heating, cooling, and power consumption while enabling predictive maintenance that extends equipment life and reduces replacement frequency. Advanced quality control systems reduce product waste, while supply chain optimization minimizes food spoilage and overproduction.

For an example of this, consider your cleaning processes. The University of Nottingham estimates that equipment cleaning consumes nearly 30% of a food processing plant’s energy and water. AI-based sensor technology cuts down on cleaning time, saves resources, and can lead to annual savings of roughly $133 million.

AI implementation lessons from industry leaders

Start small, scale fast

The most successful AI implementations in food manufacturing follow a disciplined approach that begins with focused pilots and scales based on proven results. Industry experts recommend starting small: “You don’t need to run multi-million-dollar, multi-year projects. You can run a project and in three months you can see the results. If it fails, you only spent three months on it and you can learn from it, tweak your idea and adopt better.”

Kellanova is demonstrating this mindset. Due to promising results from pilot projects, the company is weighing up where else in its network it could use AI and plans to scale AI across similar lines in the next 12 months based on these initial learnings.

Data quality is the foundation of success

Every successful AI implementation begins with a critical assessment of data quality and availability. “Good data is the absolute foundation of everything you’re building on top of AI,” says Markus Guerster, founder and CEO of MontBlancAI. “If it’s AI, machine learning, or even simpler statistics or visualization, bad data means poor decisions – trash in, trash out.”

Many companies discover that while data sources are great, the technology that collects, cleans, and stores the machine information is not good at handling significant data volume. This often requires infrastructure upgrades before AI implementation can succeed.

For larger companies, building a sound data foundation is crucial, though boards are increasingly demanding ROI from these investments. Smaller companies can learn from this “clean and organize the data first” approach while being quicker to calculate ROI and demonstrate value.

Consider your supply chain risks

“When it comes to implementing AI in food manufacturing,” explains NobleAI, “there are two smart strategies to consider. First, in today’s landscape of tariffs and geopolitical uncertainty, strengthening your supply chains and having reliable backups is a strategic benefit that can be obtained by the use of AI. Are there ingredients that could pose supply risks? AI can help you identify replacement ingredients that match or even optimize quality and performance, all in a fraction of the time it used to take.

“The same applies to ingredients affected by evolving shifting regulations that vary by geography and rapidly changing consumer preferences, where manufacturers must quickly reformulate without sacrificing product integrity. Using AI to support nearshoring or safe-shoring efforts is a practical and forward-thinking move.”

Overcoming implementation barriers

Understanding and addressing common barriers is essential for successful AI adoption.

- Cost constraints: Nearly 70% of food companies face cost barriers when adopting digital transformation solutions.

- Legacy integration: More than half (53%) struggle with integrating AI into existing systems.

- Skills gap: Nearly a third (31%) face employee reskilling challenges.

- Organizational buy-in: Interdepartmental buy-in is a struggle for 28%.

The solution?

- Phased implementation: Begin with pilot projects that demonstrate clear value before expanding.

- Partnership strategy: Work with specialized AI vendors and system integrators who understand food manufacturing.

- Training investment: Focus on upskilling existing workforce rather than wholesale replacement.

- Change management: Involve staff in the implementation process and address concerns proactively.

“Education and addressing the skills gap are key for leaders now when investing in digital infrastructure to support the adoption of AI,” notes Stephanie Brooks, Head of Research & Innovation at Foods Connected. “AI providers have an important role in educating the industry on this potential.”

Financial planning: Understanding ROI and investment requirements

Expected returns and timeline

The financial case for AI in food manufacturing is compelling when properly planned and executed:

- After introducing AI to the supply chain, 61% of manufacturing executives were able to decrease costs and 53% increased revenues. More than one-third reported a total revenue increase of more than 5%.

- A survey on AI investments found that 74% of businesses met or exceeded their expectations, demonstrating that well-planned AI initiatives deliver measurable value.

- While the average time to deploy AI is less than 8 months, companies should expect about 13 months to begin seeing benefits from AI investments.

Investment planning framework

Initial investment categories may include:

- Hardware and infrastructure like IoT sensors, cameras, edge computing devices, and network upgrades

- Software platforms such as AI/ML tools, data analytics systems, integration middleware

- Professional services that support system integration, training, change management, and ongoing support

- Organizational costs like staff training, process redesign, and temporary productivity impacts

ROI calculation approach:

Before implementing AI initiatives, plan out how you’ll measure the ROI of your solutions:

- Identify quantifiable benefits like reduced downtime, lower maintenance costs, improved yield, and decreased waste.

- Estimate soft benefits like improved decision-making, enhanced safety, and better compliance.

- Calculate total cost of ownership, including ongoing maintenance, upgrades, and support.

- Establish success metrics — define clear KPIs and measurement systems.

- Plan for scale by looking into how benefits compound as AI expands across operations.

“ROI from digital technology isn’t always immediately apparent,” adds Brooks, “so it’s crucial for technology providers and data experts to help businesses understand how AI and data can be leveraged strategically, making ROI clearer and reducing entry barriers for those wanting to truly digitize.”

Technology selection: Choosing the right partners and platforms

Selecting the right provider is a critical determinant of success in AI initiatives. Consider what you need to see results and scale, as well as what expertise and support your potential partner has to offer.

Technical requirements:

- Industry-specific functionality and understanding of food manufacturing processes

- Scalable architecture that can grow with your operations

- Real-time processing capabilities for production environments

- Integration capabilities with existing systems (ERP, MES, SCADA)

“By integrating AI with software such as an MES or SPC,” Marshall explains, “manufacturers can enhance their processes by combining real-time monitoring, predictive insights, and advanced automation, ultimately future-proofing their businesses and positioning themselves for long-term success.”

Business considerations:

- Proven track record in food manufacturing implementations

- Comprehensive support and training programs

- Clear pricing models and total cost of ownership

- Partnership approach rather than vendor relationship

Implementation roadmap: A practical guide

Like any technology investment, a careful, strategic approach to implementation will help ensure your AI initiative is ready to hit the ground running and start delivering on its promises.

Phase 1: Assessment and preparation

AI readiness assessment:

- Evaluate current data quality, accessibility, and infrastructure

- Assess organizational capabilities and change readiness

- Identify high-impact use cases aligned with business priorities

- Establish baseline metrics for ROI measurement

Foundation building:

- Implement data governance and quality management systems

- Upgrade network and computing infrastructure as needed

- Build internal AI awareness and capabilities

- Secure executive sponsorship and cross-functional support

Phase 2: Pilot implementation

Pilot selection:

- Choose focused, measurable applications with clear business value

- Start with predictive maintenance or quality control for fastest returns

- Ensure adequate data availability and quality for chosen use case

- Plan for both technical and organizational learning

Execution:

- Deploy pilot systems with minimal production disruption

- Establish monitoring and measurement systems

- Train operators and maintenance staff

- Document lessons learned and best practices

Phase 3: Scale and expand

Successful pilot scaling:

- Replicate successful pilots across similar production lines

- Integrate AI applications with existing systems

- Expand team capabilities and organizational knowledge

- Refine processes based on operational experience

Additional applications:

- Layer additional AI capabilities onto successful foundations

- Integrate multiple AI systems for end-to-end optimization

- Expand to supply chain and customer-facing applications

- Begin exploring advanced applications like generative AI

Phase 4: Strategic integration

Enterprise integration:

- Create fully connected, AI-enabled operations

- Implement advanced analytics and business intelligence

- Develop competitive differentiation through AI capabilities

- Establish continuous improvement and innovation processes

Future-proof your company with AI

As industry leaders have learned, the companies that delay AI adoption risk falling so far behind that recovery becomes extremely difficult. The technology is mature, the business case is proven, and the competitive advantages are real.

But it’s also important not to rush the implementation process — initiatives are more likely to fail without strategic thinking, careful planning, and disciplined execution. Start with a thorough assessment of your current state, identify high-impact use cases, and begin with focused pilot projects that can demonstrate clear value. Build your data foundation, invest in your people, and choose technology partners who understand both AI and food manufacturing.

The transformation of food manufacturing through AI has begun. Your company’s position in this new landscape depends on the decisions and actions you take today.

![The American contingent and Turkey’s autonomy goals: Paris Air Show Day 3 [Video]](https://breakingdefense.com/wp-content/uploads/sites/3/2025/06/Wednesday-Wrap.00_00_32_21.Still001.png?#)

![A look at the jets flying high above the Paris Air Show [PHOTOS]](https://breakingdefense.com/wp-content/uploads/sites/3/2025/06/Rafale_02-scaled-e1750268097167.jpg?#)

![[Webinar] From Turnover to Tenure: Engaging the Future of the Manufacturing Workforce](https://foodindustryexecutive.com/wp-content/uploads/2025/04/QAD-Redzone-From-Turnover-to-Tenure-Engaging-the-Future-of-the-Manufacturing-Workforce-150x150.png)