On Lebanese border, Israel’s Plasan kept rolling out armored vehicles as war raged

Given the demand from the IDF, the company was charged with keeping production up at normal or higher rates, despite the potential dangers of being so close to the border.

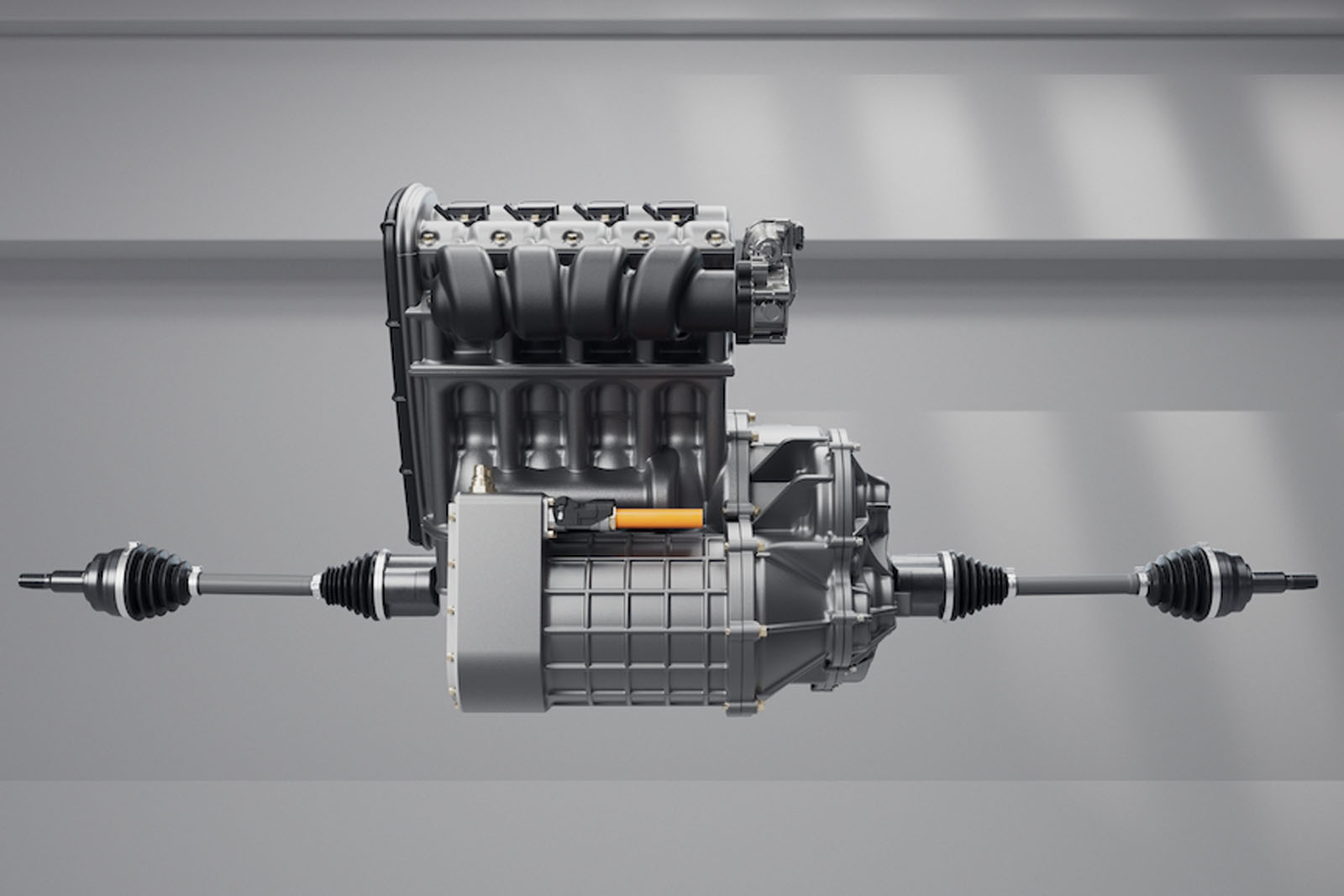

Plasan’s Sandcat “Tigris” (Photo courtesy of Plasan)

SASA, Israel — The Israeli defense company Plasan makes armored solutions for military platforms, such as producing complex armored plates for vehicles. But the company had to think about a different kind of protection in 2024 — how it keep its facilities and staff safe as the war expanded into Lebanon.

The company is located in the northern Israeli community of Sasa, around a mile from the Lebanese border, right along the front line of Israel’s conflict with Hezbollah. The company continued to roll vehicles off the line and keep up production throughout the war. During a visit to Plasan, representatives discussed how they kept up with orders and dealt with the disruptions of war.

The northern border of Israel is quiet these days. The rolling hills of the upper Galilee are preparing for spring, and some trees even have blossoms already. But for most of 2024 this area was a war zone. Israel evacuated more than 60,000 people from border communities in October 2023 when Hezbollah began rocket and drone attacks on northern Israel. Roads near the border were closed and concrete barriers were erected in many places where drivers or soldiers might be exposed to anti-tank guided missile (ATGM) fire.

“On October 7 [2023] the army came and took vehicles we had, those about to be delivered,” recalls Gilad Ariav, vice-president of marketing and business development at Plasan. And given the demand from the IDF, the company was charged with keeping production up at normal or higher rates, despite the potential dangers of being so close to the border.

The IDF needed ceramic plates for soldiers, and Plasan reopened an old line to produce them, working 24/7 to produce 35,000 plates while also increasing production of armored vehicles. While the members of the Sasa Kibbutz that is adjacent to the company were evacuated to the south, the company’s employees stayed at work. Around 50 percent of the employees were called up to IDF reserve duty. “It didn’t prevent us [from delivering]” says Ariav.

As the company provided a tour of its site, the evidence of the threats from the last fifteen months of war was still visible: In one section of the factory there are several window sections that have been impacted by various projectiles. There is also one vehicle that is missing a rear wheel and was hit by some kind of IED, and concrete barriers remain in place to protect against missile fire from Lebanon.

Members of the company described how one could often see and hear interceptions overhead during the war. Not only was Sasa targeted, but Mount Meron, which looms a mile away across a nearby valley, was often targeted because it has an IDF base near its peak. Many of the residents of the community around the company have not fully returned to their homes and schools. (Overall Plasan has around 450 employees in Israel and around 700 worldwide, with subsidiaries in the US, Australia and France.)

But officials are proud of the fact that despite the frequent sirens, need to go into shelters, and the constant threats, the work went on.

Today the company appears to be continuing to work at a fast pace to produce its armored solutions. In one area of a factory floor Ariav shows how armored plates for things such as doors of vehicles are produced. Small hexagonal ceramic pieces are placed as a layer and then they are sandwiched between metal, which the company says helps absorb blasts.

During a presentation, Ariav stressed how the company uses live trials to test its armor and solutions against explosions and projectiles, as well as running complex computer simulations. The simulations examine how different projectiles might hit a plate, or how an improvised explosive device would impact armor. This saves the cost and effort of blowing up numerous vehicles, Ariav says the simulations have proven effective in terms of final design and predicting how threats will impact armor.

In another area, the company showcased their FlexFence defense against RPGs, which looks like a kind of fence that can be draped around parts of the vehicle. The fence uses special technology to trigger the RPG and helps protect the vehicle from being penetrated, so that the damage of the blast is reduced.

The firm is also in production on a number of vehicles. One is the Sandcat, which is called the “Tigris” by the IDF. The company uses the chassis of F-550s and then adds an armored body on top of them. This is an armored solution the company calls Kitted Hull and it provides protection from all angles, including below for mines and above against small bomblets that drones can drop.

In one hangar the company is producing the Sandcats for both the IDF and what they said was another, undisclosed customer. Each has a different configuration, and employees work on the vehicles by hand, producing around ten vehicles a week.

Besides the Sandcats, a major focus for the firm are contracts for armoring JLTVs with Oshkosh as well as the Australian Redback infantry fighting vehicle, which is made by South Korea’s Hanwha. The company is also up-armoring a number of Piranhas, a family of fighting vehicles the originated in Switzerland in the 1970s and is now in its fifth generation and in use by a dozen countries.

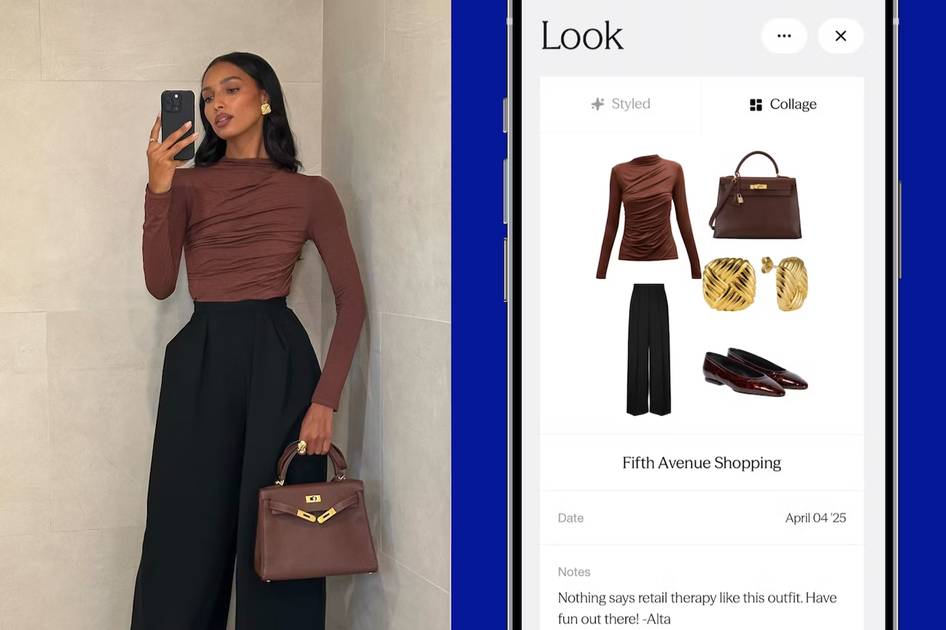

In addition, Plasan is also working on a new system called an All-Terrain Electric Mission Module (ATeMM), which is an electric-powered “modular” system that can function as a kind of trailer for a vehicle, or be used as a four-wheeled robotic unmanned vehicle.

ATeMM was first unveiled in 2021 but was tested by the IDF in the recent war in Lebanon. It was one of many vehicles in the Plasan factory that seemed to encapsulate how technology is transforming not only armored vehicles but also solutions for maneuvering forces — the kind of lesson that comes from 15 months of a multi-front war.

.jpg)