Unleashing the Underestimated Rate Capability of Graphite Anode for Potassium‐Ion Batteries by Sn(OTf)2 Electrolyte Additive

Advanced Energy Materials, Volume 15, Issue 19, May 20, 2025.

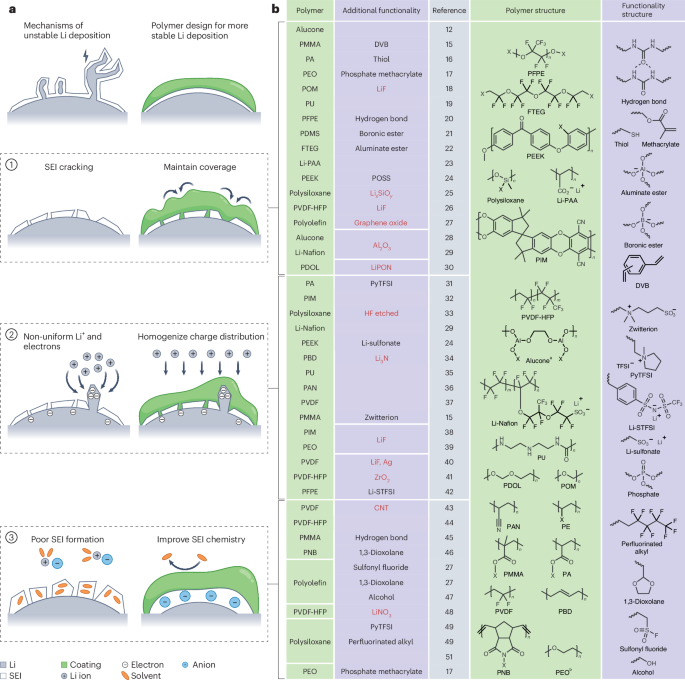

The underestimated rate capability of graphite anode for potassium-ion batteries (PIBs) is unlocked by the electrolyte with Sn(OTf)2 additive which promotes the formation of a low-impedance inorganic-rich KF/SnF2 hybrid solid electrolyte interphase on graphite. The work highlights the competitive rate capability of graphite anode which dispels the key concern regarding its commercial applicability and enriches the advantages of PIBs for high-power density.

Abstract

Graphite stands out as the most promising anode material for potassium-ion batteries (PIBs) due to its cost-effectiveness and ideal low-potential platform. However, the perceived poor rate capability of graphite has become a key concern for its commercial application in PIBs. Herein, the above understanding on the poor rate capability of graphite is updated. Without modifying graphite structure, by simply introducing a tin trifluoromethanesulfonate (Sn(OTf)2) additive in phosphate-based electrolyte, the graphite in K||graphite half-cell can deliver a capacity of 240 mAh g−1 at a high rate of 2 C (1 C = 279 mA g−1) and operates for 1000 cycles with negligible degradation. Moreover, an unprecedented rate capacity of ≈200 mAh g−1 for graphite anode at 4 C is achieved in a three-electrode K|K ref|graphite cell configuration where the interference of the K metal counter electrode is eliminated. Unlike structure modification strategies, such remarkable rate performance is originated from the low-impedance inorganic-rich KF/SnF2 hybrid interphase on graphite. Thus, the effectiveness of the electrolyte regulation strategy highlights the underestimated rate capability of graphite anode. This renewed insight dispels the concern regarding the commercial applicability of graphite anode and enriches the advantages of PIBs for high-power density.