The Value of Device Characterization for the Optimization of Organic Solar Cells

Advanced Energy Materials, Volume 15, Issue 24, June 24, 2025.

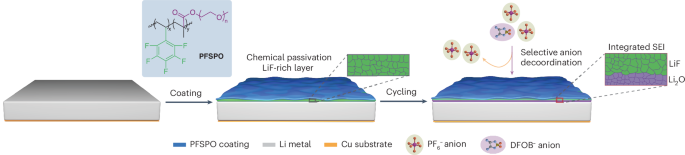

Using the example of organic photovoltaics (OPV), this study examines whether and when additional measurements can be helpful in process optimization. A virtual laboratory based on real solar cells serves as a benchmark function to compare two different approaches for process optimization, namely black-box optimization (black circle) and model-based optimization (green circle). In particular, the additional information about the active layer thickness can be used to accelerate the process optimization.

Abstract

In addition to achieving record efficiencies of ≈20%, organic photovoltaics (OPV) has to overcome several additional challenges. These include researching environmentally friendly solvents, improving stability, yield, and scaling up to industrial standards in terms of cell size and mass production. However, identifying the optimal candidates from the countless material combinations and determining the exact process parameters is like looking for a needle in a haystack. Process optimization usually comprises phases such as device fabrication, measurement, and evaluation, concluding with the experimental design of the next round of device making. Given the extent of the process parameter space, this optimization process can be extremely time-consuming. However, as optimization algorithms mainly based on mathematical models become more prevalent in automated laboratories, the question arises of how to include physics domain knowledge based on device characterization of the samples into the algorithmic optimization process. To address this question, a benchmark function is created using experimental solar cell data originating from hundreds of organic solar cells prepared with different processing conditions. This benchmark function is used to test and compare different optimization approaches to quantify under which conditions physical domain knowledge can improve the speed of process optimization in an experimental laboratory.