Scalable All‐Vacuum‐Processed Perovskite Solar Cells Enabled by Low Energy‐Disorder Hole‐Transport Layer

Advanced Energy Materials, EarlyView.

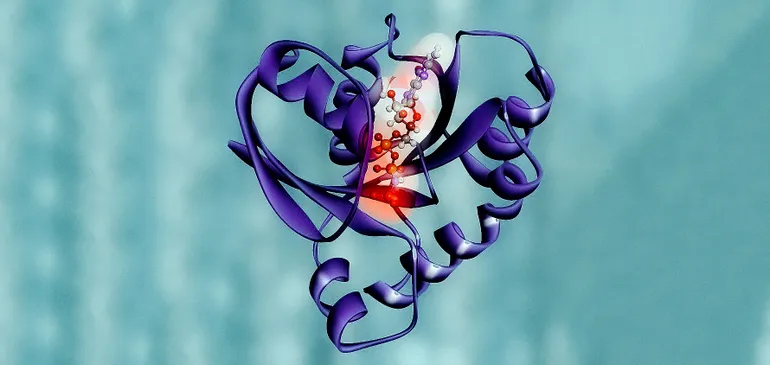

Vacuum-processable TAA-tetramer is introduced as a hole-transport layer (HTL) in all-vacuum-processed inverted perovskite solar cells (PSCs). Through the reduced structure, energy disorder, and improved surface features of the HTL, enhanced performance and operational stability of the PSCs are realized. Furthermore, large-area single cells and modules are successfully demonstrated with minimal efficiency loss during their scale-up.

Abstract

As perovskite solar cells (PSCs) require higher standards for commercial applications, all vacuum-processed PSCs should become a key in future manufacturing processes of scalable PSCs compared to their currently dominating research types based on solution processes. In fact, vacuum deposition of high-quality organic hole-transport layers (HTLs) is crucial for successful fabrication of all vacuum-processed scalable PSCs. Here, the study develops a triarylamine-based single oligomer (TAA-tetramer)−a miniaturized-molecular form of the well-known poly(triarylamine) (PTAA)−as a vacuum-processable HTL in inverted PSCs. The well-defined structure and monodisperse nature of the TAA-tetramer render strong intermolecular π−π interactions and/or molecular ordering, resulting in simultaneously enhanced quasi-Fermi level splitting and hole-transport efficiency of the perovskite. The resulting all-vacuum-processed inverted PSCs exhibits a high power conversion efficiency (PCE) of 23.2%, which is record-high performance reported among all-vacuum-processed PSCs, with exceptional device stabilities. Furthermore, the all-vacuum-deposition process allows the fabrication of efficient PSCs and modules with reliable scalability and minimized efficiency loss during scale-up. Notably, the proposed HTL enabled high-efficiency large-area (25 cm2) single-PSC with a PCE of 12.3%, representing one of the largest active areas and the highest performance ever reported for the large-area device. A promising strategy for developing efficient, stable, and scalable PSCs for all-vacuum processes is presented.