Peptide Display Directed Assembly of Biopolymer Core–Silica Shell Particles

Advanced Healthcare Materials, EarlyView.

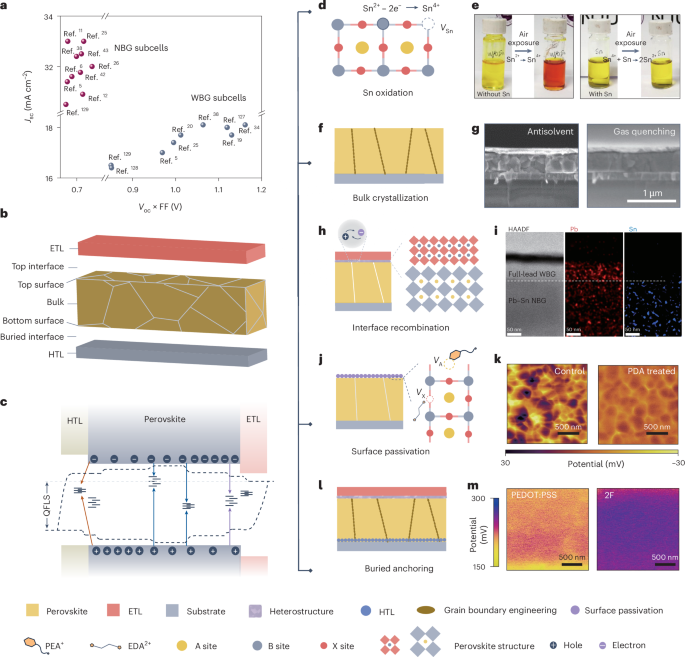

Bacterial cells are engineered to produce biopolyester particles displaying peptides mediating growth of silica. Peptide-coated biopolyester particles are treated with silica precursors and silica shell formation is studied. Transmission electron microscopy shows silica-coated BPs which are formed after the silicification treatment. Characterization of physicochemical and biological properties as well as uses in drug delivery are shown.

Abstract

The unique hierarchical core–shell structures of silica capsules contributing to delivery of active compounds have attracted broad interest. To overcome the limited cargo-loading capacity of silica capsules but harness the silica mediated cargo protection, Escherichia coli is engineered to efficiently assemble submicrometer-sized biopolyester particles (BPs) that densely display the positively charged RK1 peptide ((RKK)4G3Y), which mediates nucleation and growth of silica. The peptide-coated BPs are tested as biomimetic template and treatment with silica precursors results in formation of BP core–silica shell structures. Electron microscopy reveals changes in BP surface morphology consistent with silica shell formation further confirmed through Fourier transform infrared spectroscopy. Thermogravimetric analysis shows 0.10 g of silica shell per gram of BPs is formed, with no impact on crystallinity as assessed by X-ray diffraction. The payload of the lipophilic biopolyester core for the lipophilic model compound, curcumin, increases to an encapsulation efficiency of 23.6%. Silica coating of BPs does not cause cytotoxicity and BPs show efficient cellular uptake. This study presents an innovative and environmentally benign approach for efficiently assembling robust biopolyester core–silica shell structures. The nontoxic polymer core provides drug payload capacity, protected by a silica coating ideal for controlled drug delivery applications.