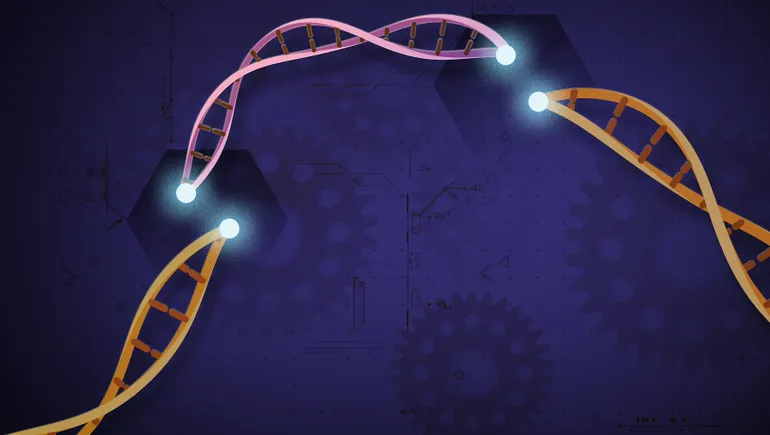

Transient Chemo‐Mechanical Model of Lithium Plating Impacted by External Pressure

Advanced Energy Materials, Volume 15, Issue 16, April 22, 2025.

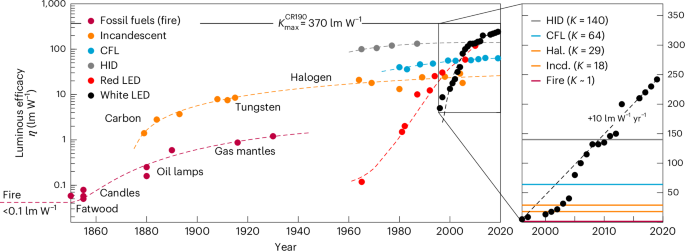

The evolution of a lithium anode due to stripping and plating under stack pressure is modeled using a coupled finite-element simulation. Early interfacial movement and stability is heavily dependent on pressure and lithium mechanical properties assumed at the microscale. Over a full charge–discharge cycle, the accumulation of lithium hardening leads to similar end state morphologies regardless of stack pressure.

Abstract

Lithium anodes show great promise in commercial applications, but are hindered by lithium plating and dendrite growth which cause safety concerns during long-term cell operation. Stack pressure is experimentally observed to improve cell lifetime; however, the relationship between stress and lithium deposition has remained difficult to elucidate. In this work, a transient, 3D, finite-element model of the evolution of a lithium anode due to stripping and plating is developed. The evolution of a microscale protrusion on the anode surface is tracked over one charge-discharge cycle with respect to stack pressure and lithium yield strength. Lithium plastic deformation, nonconformal anode-separator contact, and separator porosity effects are accounted for. Over the course of several hours of stripping/plating, the anode surface evolves to a similar morphology under pressure regardless of the initial conditions due to lithium plastic deformation and hardening. The rate of this evolution highly depends on the applied pressure and assumed lithium yield strength.

.jpg)