High‐Performing Perovskite/Ruddlesden‐Popper Fuel Electrode for High‐Temperature Steam Electrolysis

Advanced Energy Materials, Volume 15, Issue 18, May 13, 2025.

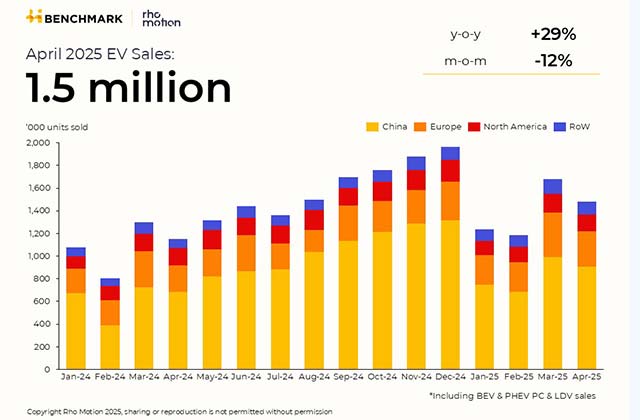

By combining perovskite and Ruddlesden-Popper phases, a Ni-free fuel electrode with exceptional electrocatalytic activity and ionic conductivity is developed. This approach minimizes polarization resistance, achieving 0.053 Ω cm2 at 800 °C and 1.084 W cm−2 power density. The findings highlight its potential as a superior alternative for solid oxide cell applications.

Abstract

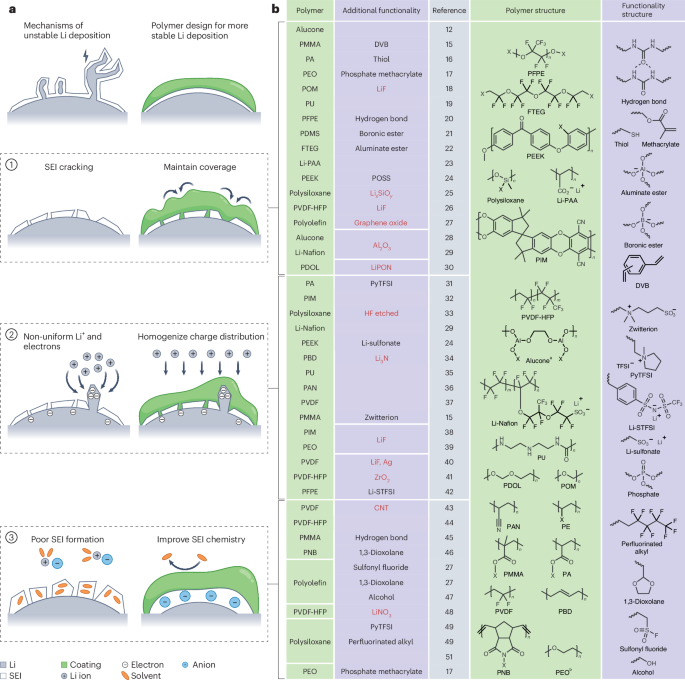

Ruddlesden-Popper (RP) oxides have emerged as a promising alternative to Ni cermet electrodes for high-temperature steam electrolysis due to their superior oxide ion mobility and conductivity. Combining RP with perovskite (P) can provide superior electrocatalytic activity toward hydroxide oxidation and reduction reaction, driving higher efficiency in solid oxide cells (SOC). This work provides a novel approach to enhancing SOC performance by employing A-site Ce-substituted Sr0.6Pr0.4-xCexMnO3 (x = 0.1-0.3) electrodes, investigating their phase evolution, crystal properties, and cation oxidation states under oxidizing and reducing atmospheres. X-ray diffraction analysis of heat-treated powder in a reducing atmosphere revealed forming mixed P and RP structures at 600–800 °C for x = 0.1 and 0.2, which provides excellent conductivity and electrocatalytic activity. Consequently, outstanding cell performance is achieved, with low polarization resistances of 0.053 ± 0.004 Ω cm2 at 800 °C. The voltage response at different current densities in an electrolyte-supported cell revealed a high power density of 1.084 W cm−2 in fuel cell operation and a current density of 1.00 A cm−2 at the thermoneutral voltage at 850 °C in steam electrolysis. Moreover, a low overpotential degradation rate of 45 mV kh−1 demonstrated the remarkable potential of the SPCM electrode as a promising Ni-free candidate for SOC application.