Enabling Metal Fluorides Cathodes at Elevated Temperatures Using a Molten Salt Electrolyte

Advanced Energy Materials, EarlyView.

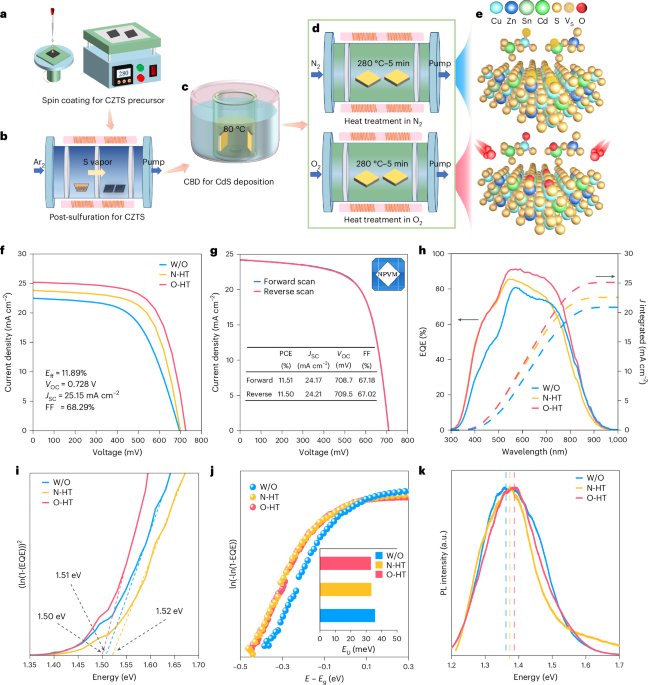

The synergistic effect of using organic solvent-free electrolytes (OSFEs) and chemical vapor deposition (CVD) coating enables long cycle number of previously uncyclable conversion-type nickel fluoride (NiF2) cathode at elevated temperatures. CVD carbon coating not only mitigates the dissolution of active materials, but also reduces the parasitic reactions at the carbon/OSFE interface, therefore boosting the cycle performance of NiF2.

Abstract

Conversion-type metal fluorides (MFs) cathodes are promising candidates for high-energy lithium–ion batteries. However, their cycling performance is limited due to the decomposition of organic solvent electrolytes at the cathode/electrolyte interface and the dissolution of active materials during cycling, especially at elevated temperatures (above 60 °C). To address these challenges, a thermally stable, organic solvent-free electrolyte (OSFE) composed of three low melting alkali perfluorinated sulfonimide salts is developed, which helps to minimize the undesirable solvent decomposition. Additionally, chemical vapor deposition technology is employed to apply a conformal carbon coating to a representative MF, NiF2, effectively preventing the dissolution of active materials. The synergistic effect of OSFE and carbon coating enables a previously uncyclable NiF2 cathode, which exhibits a high reversible discharge capacity of 450 mAh g−1 after 160 cycles at 80 °C. Moreover, by incorporating 10 wt.% Li10GeP2S12 (LGPS) into the OSFE, the cycle number of NiF2 is extended to 300 cycles, maintaining an impressive discharge capacity of 350 mAh g−1 at 60 °C. These advancements highlight the potential for successful operation of MFs at elevated temperatures using OSFE, paving the way for their practical applications and future commercialization.