Cathode Upcycling for Direct Recycling of Lithium‐Ion Batteries Using a Precipitation Approach

Advanced Energy Materials, EarlyView.

To improve the circularity of lithium-ion batteries, researchers develop a low-cost method to increase the energy density of directly recycled cathodes. Through a precipitation process, low-nickel materials are converted to high-nickel compositions. Using synchrotron 3D X-ray imaging and diffraction, they track nickel diffusion during high-temperature relithiation. The process preserves particle structure and offers significant environmental and economic benefits over traditional recycling.

Abstract

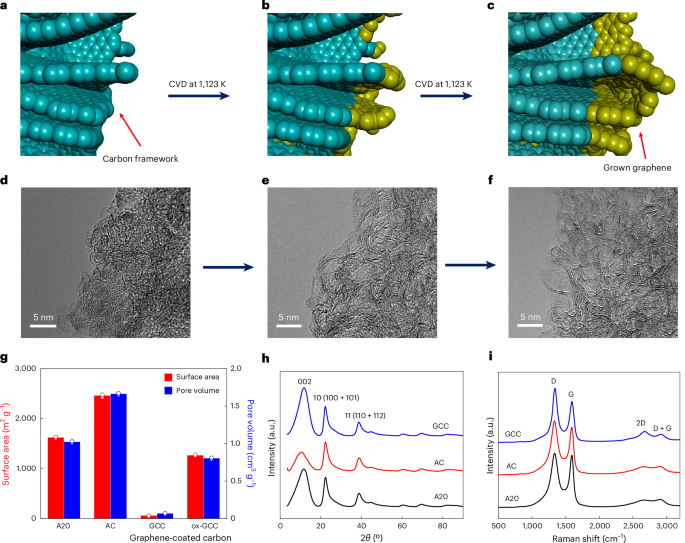

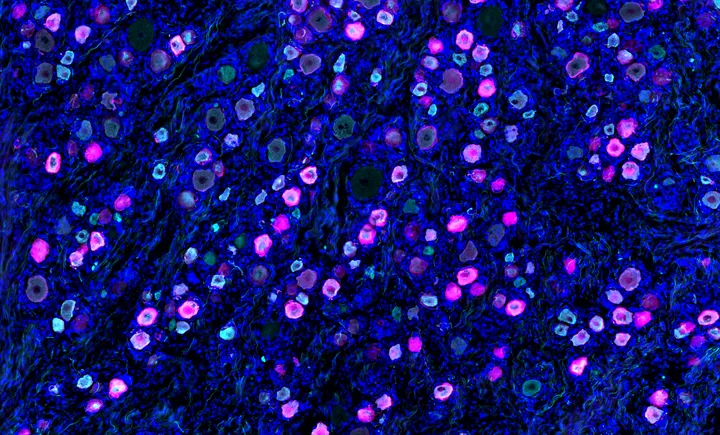

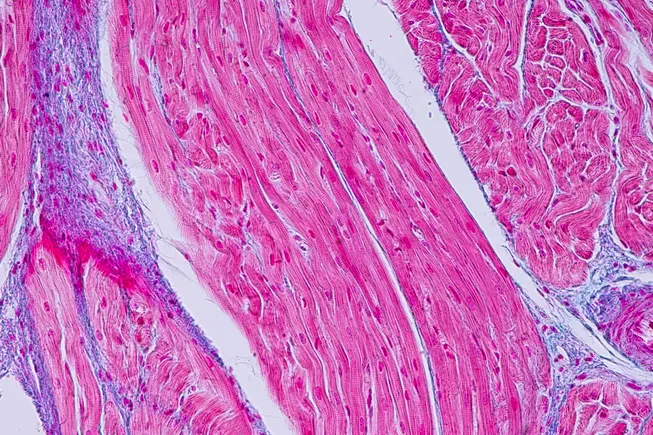

With the increased production of electric vehicles to reduce carbon emissions, the lithium-ion battery market to supply those vehicles has grown dramatically. To enhance battery sustainability and circularity, direct recycling methods aim to recover intact cathode materials. However, end-of-life cathode materials are typically 15–20 years old and often have lower energy density compared to current cathode materials. To address this challenge, a rapid precipitation process is developed to boost energy density by converting low Ni-compositions, LiNi0.33Co0.33Mn0.33O2 (NMC111), into higher Ni-compositions (NMC622). This process forms a Ni-rich coating on cathode particles that diffuses into the core upon high-temperature relithiation, increasing compositional homogeneity. The upcycling process leverages existing infrastructure, offering low capital cost and minimal additional chemical input. Through ex situ tomographic transmission X-ray microscopy (TXM), 3D Ni:Co elemental mixing is quantified, confirming that elemental content evens at the secondary particle level with a mean NMC622 composition upon relithiation. However, elemental gradients remain in the single crystalline primary particles. Ex situ high-resolution and in situ wide-angle X-ray diffraction reveals concurrent structural changes during the relithiation process. These findings provide key insights into the structural and chemical mechanisms of elemental diffusion to obtain further improvements of increased capacity and retention through compositional conversion of cathode materials.

![[Video] The Weekly Break Out Ep. 19: Army aviation’s shakeup and the F-35’s future](https://breakingdefense.com/wp-content/uploads/sites/3/2025/05/EP-19-THUMB-play-button.jpg?#)