Automating Recalls Dramatically Improves Speed, Accuracy, & Traceability

By Roger Hancock, CEO of Recall InfoLink Key takeaways: Automating recall processes significantly improves speed, accuracy, traceability, and communication — helping food businesses act swiftly during recalls and better protect […]

By Roger Hancock, CEO of Recall InfoLink

Key takeaways:

-

Automating recall processes significantly improves speed, accuracy, traceability, and communication — helping food businesses act swiftly during recalls and better protect public health.

-

Manual systems are outdated and risky, leading to slower, less effective recalls, while automation enables real-time product tracking, streamlined communication, and improved regulatory compliance.

-

Adopting user-friendly, affordable recall tech helps companies reduce costs, protect brand reputation, and ensure teams are prepared before a crisis occurs.

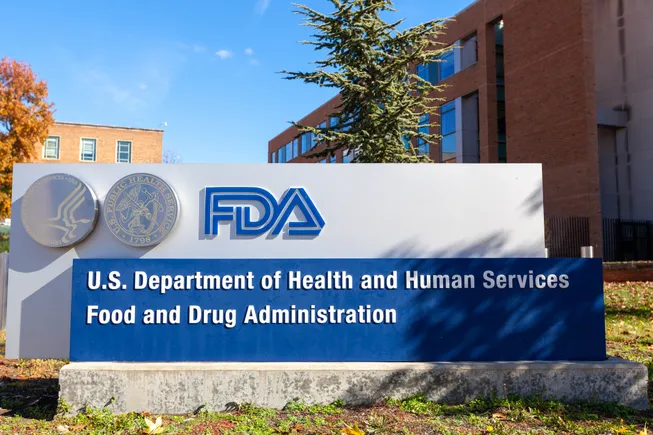

Recalls have remained a constant in 2025, with frozen meals, egg whites, hummus, ground beef, and more foods being recalled already this year. These aren’t isolated incidents. In fact, the number of recalls doubled last year over the previous year. Even the most safety-conscious food brand can have a food safety breach and subsequent recall. The variety of possibilities for error ranges broadly from a supplier inadvertently bringing them contaminated products, an employee making an innocent mistake, or foods being temperature-abused in transit. Therefore, food businesses must be prepared to effectively handle a recall, with the proper systems and tools in place to mitigate public health risks (and other potential recall fallout).

Yet, many food businesses resist changing their systems, instead relying on manual processes because “it’s the way we’ve always done things.” Unfortunately, antiquated manual systems can prolong recalls, increasing damage and threatening public health. At a time when every moment counts, food brands don’t want employees scrambling to manually call trading partners, attempting to share information using paper files, or trying to pinpoint the exact whereabouts of contaminated products using an old Excel spreadsheet. These manual efforts are slow, ineffective, high-risk, and error-prone.

It’s time for all food businesses to rely on technology and automation.

The many benefits of automation

Automation has improved many aspects of the food industry by enabling faster, more efficient processes. For instance, artificial intelligence has improved data collection and analysis, robotics has optimized repetitive actions, and automated systems have reduced the risks of human error. Automation is also a game-changer for recalls, boosting accuracy, traceability, efficiency, communication, not to mention reducing the scope of the recall and minimizing product loss.

Automating recalls comes with many significant benefits, as it can dramatically improve:

Visibility and traceability: One safety breach can affect thousands of products across multiple states. Using manual methods means that it can be time-consuming to identify the contamination source and locate all impacted products, but automated recall processes improve visibility and traceability in real-time. Automation tracks products from source to shelf, so trading partners can more accurately locate and pull contaminated products from the supply chain, ideally before they reach stores, restaurants, and consumers’ homes.

Speed: When food businesses have sophisticated systems in place, it guides their teams during the stressful recall process. Prebuilt workflows maximize efficiency, allowing recalls to launch in minutes. Real-time dashboards offer visibility into recall progress, stakeholder responses, and product recovery. Digital traceability systems map product movement instantly. And integrated contact databases accelerate notification to key stakeholders.

Communication: Recalling companies must communicate swiftly, accurately, and honestly to key audiences, including trading partners, regulators, and consumers. Push notifications ensure every stakeholder gets consistent, timely communication to drive desired actions (like having trading partners pull products, and having consumers return recalled products to the point-of-purchase). Mobile-first platforms enable rapid communication across distributed stakeholders. Accurate and current contact information is essential.

Compliance: Food businesses can use tech tools to automate and elevate their record-keeping, which is essential for compliance. All recall activities must be properly documented, a difficult and daunting task using manual methods. Handwritten records can be messy or even misplaced, and Excel spreadsheets often have errors and issues with version control. However, automation makes it smoother, easier, and more streamlined to generate accurate reports.

Brand reputation: Food companies must prioritize protecting public health, and elevating recall efforts can also help them minimize reputational damage. Consumers expect to see the recalling company act quickly and properly, removing contaminated products from the marketplace. If a food brand is upfront and honest about the incident — spotlighting the innovative technologies they’re using to ensure a swift and thorough recall — they can maintain consumer confidence, trust, and loyalty. On the other hand, if the recalling company uses ineffective processes, issues incomplete recalls, or lacks transparency about what happened, it can erode consumer confidence, which can be difficult to restore.

Cost-savings: The cost of a single recall can reach $99.9 million. Additional recall repercussions may include decreased sales, plummeting stocks, factory shutdowns, negative press, and scathing social media posts, which can be financially damaging for the recalling company. Automating the recall process can cut recall times in half (or more), and can result in labor and cost savings up to 90% — a substantial amount.

Don’t fear automated processes or technology

The food industry has been slower than other sectors to transition away from manual processes and adapt tech solutions. Even in today’s tech-focused culture, some food businesses are still using pen and paper systems, data spreadsheets, and other antiquated tools.

Some food brands may resist tech solutions and automation, worrying that these technologies are financially out-of-reach. In truth, today’s tech solutions are more affordable than ever before, making them accessible for food businesses of all sizes and budgets. Plus, technology can actually save companies substantial money by optimizing operations, maximizing efficiency, and reducing the financial, legal, and reputational damage from recalls.

Often, companies fear that tech-driven systems will be too complicated to implement and utilize, or that their employees won’t be able to adapt successfully. But modern tech tools are user-friendly and offer many important benefits, so it’s well worth the effort to switch.

Incorporate recall automation now — before you need it

When issuing a recall, food brands must use the right tools to maximize speed, accuracy, and transparency — and automation can help them accomplish this.

Audit your current recall process to identify where manual tasks create bottlenecks. Choose platforms built for recall execution to boost accuracy, efficiency, speed, etc. Leverage tools that offer integrated contact databases, real-time dashboards, audit-ready reporting, and interoperability with your supply chain. Train your team on these innovative systems before you need them, ensuring that they’re comfortable with the new tools and know how to use them in a recall situation.

Automation is elevating all aspects of the food industry — including how we manage recalls. It’s time to pivot from antiquated, error-prone, time-consuming manual processes and embrace automation. Automating the recall process allows food brands to act more quickly, boost accuracy and traceability, improve communication, mitigate risks, maintain brand reputation, and (most importantly) protect public health.

Roger Hancock, CEO of Recall InfoLink is one of the world’s foremost experts on recalls, with experience that spans the retail, tech, data, regulatory, and supply chain. Recall InfoLink makes recalls faster, easier, and more accurate across the supply chain to protect consumers and brands. As the only company focused entirely on recalls, Recall InfoLink’s solutions drive immediate action, streamline the recall process, and simplify compliance. Recall InfoLink helps brands become Recall Ready by standardizing data, collaborating with their supply chains, and practicing recall simulations.