Revolutionising Warehousing Adaptability

The role of warehouses has undergone a fundamental shift. No longer just storage facilities, they now serve as high-tech, highly efficient hubs driving the modern supply chain. For BCMPA members in contract manufacturing, packing, fulfilment, and logistics, staying ahead requires smart integration of technology, flexible operations, and a focus on green practices. Agility in Warehousing [...] The post Revolutionising Warehousing Adaptability first appeared on Warehouse & Logistics News.

The role of warehouses has undergone a fundamental shift. No longer just storage facilities, they now serve as high-tech, highly efficient hubs driving the modern supply chain. For BCMPA members in contract manufacturing, packing, fulfilment, and logistics, staying ahead requires smart integration of technology, flexible operations, and a focus on green practices.

Agility in Warehousing

With rising customer expectations, global supply chain pressures, and the e-commerce boom, modern warehouses need to be resilient, making agility and flexibility the new priority. Modern supply chains are no longer linear – they are dynamic and unpredictable. Businesses need modular and scalable warehouse designs that can expand, or contract, based on fluctuating customer requests and call-offs.

On-demand warehousing is growing, allowing businesses to access flexible storage solutions without long-term commitments. In addition, micro-fulfilment centres are emerging in urban areas, helping brands provide faster delivery times while reducing last-mile costs.

Smart Investment

Automation is driving major change in BCMPA member and other warehouse operations, and when paired with digitalisation, it boosts efficiency and precision. Robotics, automated guided vehicles (AGVs), and AI-driven systems are enhancing speed, accuracy, and scalability, however the real transformation comes with the integration of cloud-based software. For value-added services – such as contract packing, and fulfilment – digitalisation provides real-time data access, improved inventory visibility, and centralised control. This allows for optimised stock levels, automated order fulfilment, efficient labour deployment, and more accurate demand forecasting to drive efficiencies and cost-benefits.

Sustainability at Scale

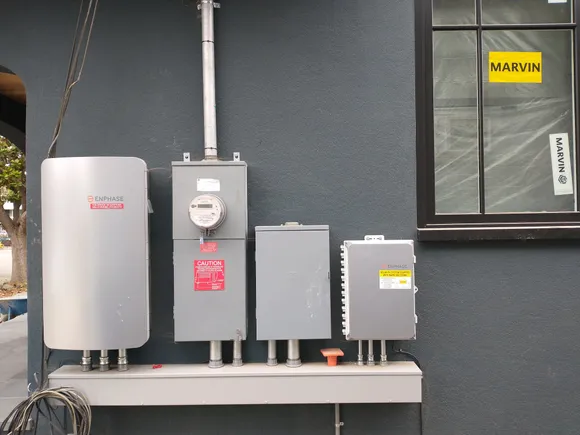

As environmental concerns continue to rise, BCMPA members are adopting a range of eco-conscious warehousing practices to reduce their carbon footprint and align with Environmental, Social, and Governance (ESG) objectives.

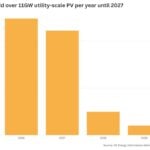

One of the most impactful changes is the transition to regenerative energy solutions, such as kinetic flooring and solar-powered warehouses, which significantly reduce reliance on non-renewable energy. Also process improvements driven by digitalisation, are helping cut down on waste and inefficiencies through ensuring the right stock is on the right equipment at the right time. Additionally, sustainable packaging is becoming a key consideration, with businesses moving toward biodegradable materials and reusable shipping options as well as working hard to minimise wastage across all aspects of the supply chain. By prioritising green initiatives, BCMPA members are not only helping protect the environment but also reducing operational costs, demonstrating how third-party outsourcing providers serve as custodians of their customers’ brands. Through close collaboration, they work to enhance and champion the brands they support, ensuring sustainability and efficiency align with their clients’ core values.The post Revolutionising Warehousing Adaptability first appeared on Warehouse & Logistics News.

.jpg)