Plastic Deformation of LiNi0.5Mn1.5O4 Single Crystals Caused by Domain Orientation Dynamics

Advanced Energy Materials, Volume 15, Issue 19, May 20, 2025.

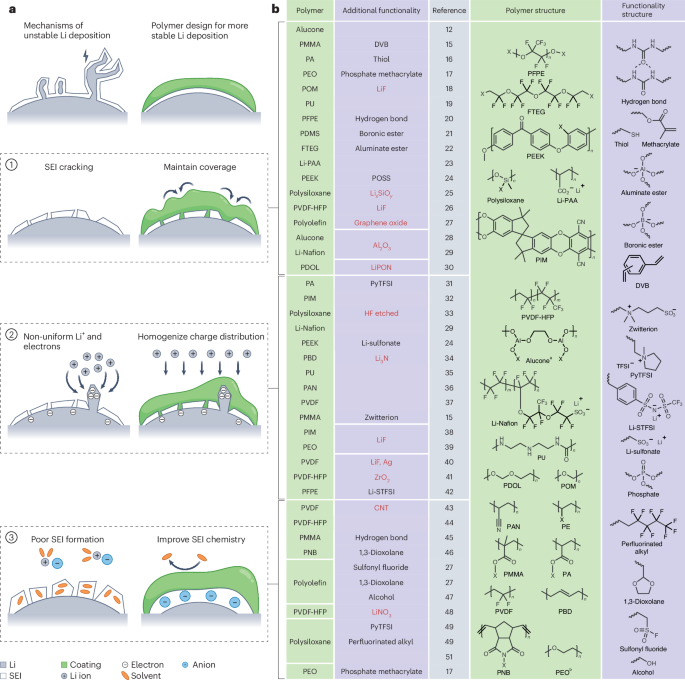

The nanoscale mechanisms of Li-ion deintercalation in battery cathodes, particularly the role of crystallographic defects, remain unclear. Using scanning X-ray diffraction microscopy and multi-crystal diffraction, microstrain and lattice misorientations are examined in LMNO cathodes particles during and after cycling. Results reveal irreversible lattice changes, inter-particle heterogeneity, and defect-driven degradation highlighting intricate features of cathode degradation mechanisms.

Abstract

The nanoscale mechanisms of ion deintercalation in battery cathode materials remain poorly understood, especially the relationship between crystallographic defects (dislocations, small angle grain boundaries, vacancies, etc), device performance, and durability. In this work, operando scanning X-ray diffraction microscopy (SXDM) and multi-crystal X-ray diffraction (MCXD) are used to investigate microstrain and lattice tilt inhomogeneities inside Li1 − x Ni0.5Mn1.5O4 cathode particles during electrochemical cycling and their influence on the material degradation. Using these techniques, microscale lattice degradation mechanisms are investigated inside single crystals, extend it to an inter-particle scale, and correlate it with the long-term degradation of the cathode. During cycling, a crystal lattice deformation is observed, associated with phase transitions and inherent lattice defects in the measured particle. Residual misorientations are observed in the structure even after full discharge, indicating an irreversible structural change of the lattice. However, after long-term cycling such lattice misorientations together with active material dissolution are further exacerbated only in a subset of particles, suggesting high heterogeneity of degradation mechanisms between the cathode particles. Selective degradation of particles could be caused by varying crystal quality across the sample, highlighting the need for a deep understanding of defect microstructures to enable a more rational design of materials with enhanced durability.