Improving Cycling Stability of Ni‐Rich Cathode for Lithium‐Metal Batteries via Interphases Tunning

Advanced Energy Materials, Volume 15, Issue 10, March 11, 2025.

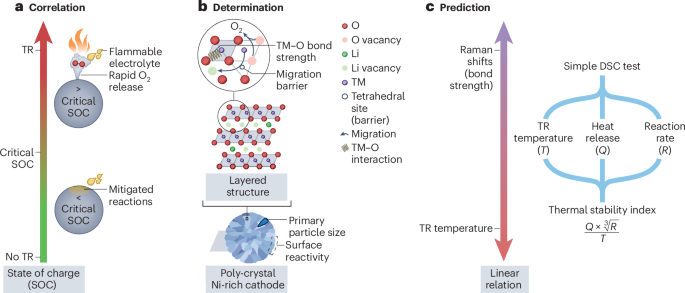

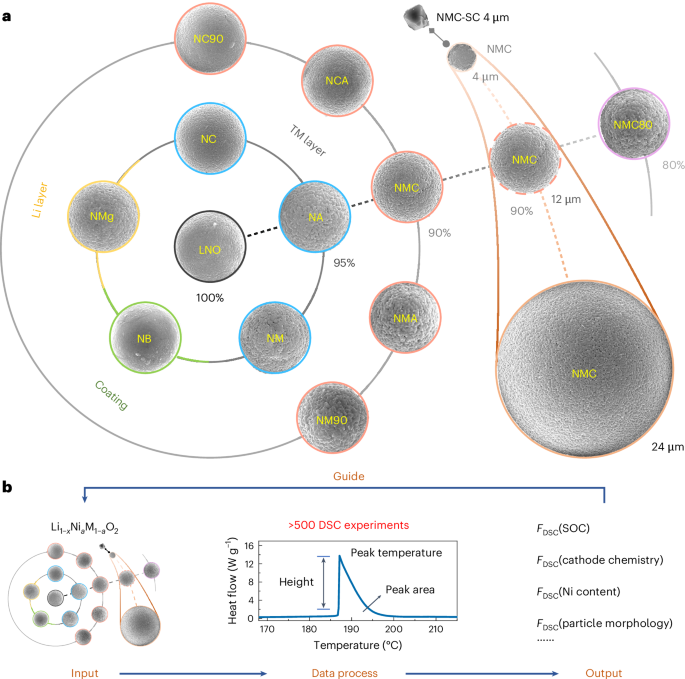

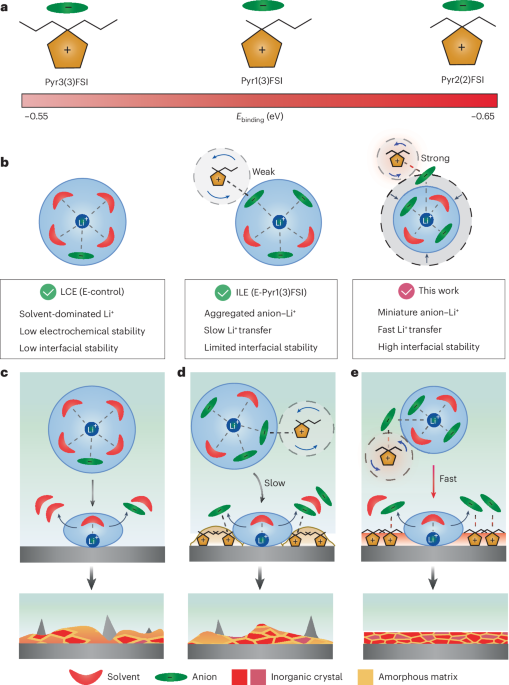

High-voltage Li-metal batteries often suffer from severe capacity fading due to the degradation of the cathode at high voltages and parasitic reactions between the electrolyte solution and both electrodes. The combination of a morphology-engineered Ni-rich cathode and the formation of a high-quality surface film ensures long-term stability by minimizing nonuniformity.

Abstract

Combining Li-metal anodes (LMAs) with high-voltage Ni-rich layered-oxide cathodes is a promising approach to realizing high-energy-density Li secondary batteries. However, these systems experience severe capacity decay due to structural degradation of high-voltage cathodes and side reactions of electrolyte solutions with both electrodes. Herein, the use of multi-functional additives in fluoroethylene carbonate-based electrolyte solutions that enable the operation of successfully rechargeable high-voltage (4.5 V) Li-metal batteries (LMBs) with high areal capacity (>4 mAh cm−2) are reported. Customized electrolyte solutions are pivotal in passivating the electrodes, minimizing microcrack formation, and ensuring that current is uniformly distributed within cathode particles. The developed electrolyte solution protects the LMA by forming a very stable and effective solid–electrolyte interphase. Together with the Li[Ni0.78Co0.1Mn0.12]O2 cathode material, which is composed of radially aligned rod-shaped primary particles, the developed high-voltage LMB containing 20 mg cm−2 of cathode material delivers a high specific capacity of 230 mAh g−1 at 0.1 C and retains >86% of its initial capacity after 200 cycles at 0.5 C. This study highlights the significance of controlling the interfacial structure via electrolyte solution modification and the use of cathode materials with engineered morphologies that enhance mechanical stability.