A Novel Kinetically‐Driven Approach to Forming Columnar {110}‐textured Lithium Metal Anodes with Extended Cycle Life

Advanced Energy Materials, EarlyView.

The impact of electrode kinetics on lithium texture is an unexplored area despite its potential to provide straightforward texture manipulation toward improved performance of lithium metal anodes (LMAs). A kinetically-driven growth rate selection approach is identified to form columnar {110}-textured LMAs. The orientation constraint improves plating/stripping homogeneity, suppressing dendrite formation and electrolyte consumption for extended cycle life under lean-electrolyte conditions.

Abstract

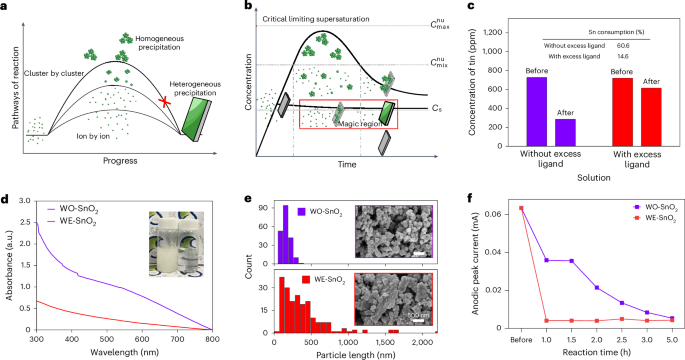

Constructing {110}-textured lithium (Li) metal anodes is a promising strategy to extend battery life. While preparation of such anodes has been the subject of a few studies, their focus has been exclusively on thermodynamically-driven (equilibrium) strategies. Through a systematic screening of bath conditions, the study reported here identifies a novel kinetically-driven protocol that enhances the volume fraction of {110} texture by more than fivefold compared to equilibrium approaches. The protocol involves Li deposition at high current densities or low temperatures in a commonly used LiNO3-containing ether-based electrolyte. Columnar {110}-oriented grains are formed through a growth rate selection process arising from the stronger electronic coupling and faster electron transfer rate between Li(110) and Li+ cations compared to other lattice planes. LiNO3 plays a crucial role by inhibiting the deposition on the Li(110) plane less than the other planes. Simple bath condition adjustments yield optimized {110}-textured Li anodes with improved plating/stripping homogeneity that suppresses dendrite formation and electrolyte consumption, resulting in extended cycle life in lean-electrolyte full cells. This kinetically-driven approach offers mechanistic insight into Li texture formation and a promising route to high-performance Li metal anodes.