Elevated Practical Volumetric Density and Cyclic Durability of Selenium Cathodes by Powder Microspheroidization and Kilogram‐Scale Atomic Layer Deposition Techniques

Advanced Energy Materials, Volume 15, Issue 19, May 20, 2025.

Powder microspheroidization coupled with O-PPy-mediated ALD technique proves an effective way to settle knotty issues in Se cathodes, endowing them with elevated powder tap density (2.06 g cm−

3), areal Se loading density (8.43 mg cm−2) and long cycling. Such packed pouch cells are thinner than random-shaped counterparts, with an exceptionally high Ev

beyond 1158.3 Wh L−1.

Abstract

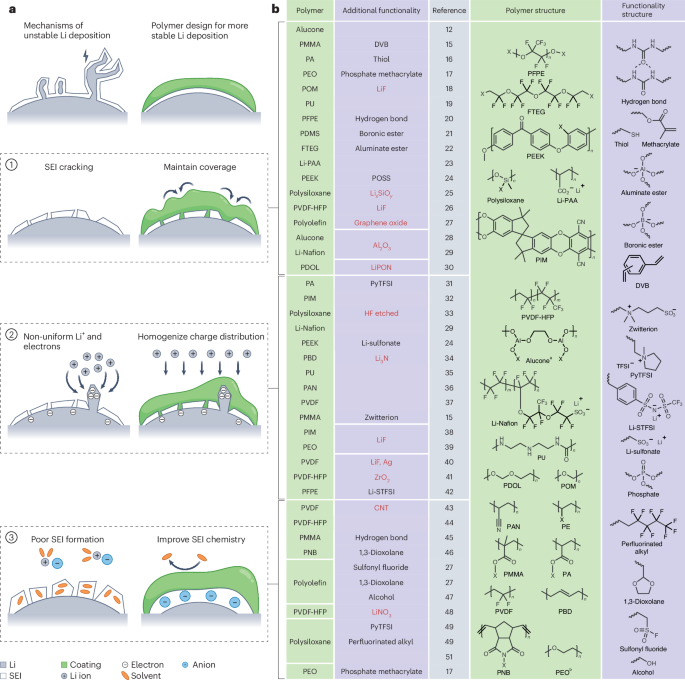

Practical usage of high-energy chalcogen cathodes, typically like selenium (Se), is plagued by compromised volumetric energy density and cyclic lifespan in pouch cells, due to the low cathode compactness and continuous Li2Sen shutting issues. Inspired by classic close-packing theories and self-limiting configurations, we propose to construct high-tap-density microsphere cathodes made of Se nano yolks and N-rich carbon (NC)-TiO2 shells via a kilogram-scale atomic layer deposition (ALD) technique. The utilized particle microspheroidization strategy makes powders approach the Max. theoretical volume fraction of 0.64, achieving intrinsically high tap density (2.06 g cm− 3) and large areal Se loading ratio beyond 8.4 mg cm−2 after slurry coating. A molecular-engineered oxidative polypyrrole (O-PPy) layer covered on Se surfaces plays an indispensable role in guaranteeing smooth ALD implementation. The formed robust NC-TiO2 microreactors solidly confining Se actives in spatial regions help to expedite Li2Sen phase conversions, rendering cathodes with a remarkable capacity of 502 mAh g−1 (0.5C) and far lessened capacity decay in all cycling. Their assembled pouch cells are ∼20% thinner than those of random-shaped counterparts, showing an exceptionally high Ev value over 1158.3 Wh L−1. This work may propel the advent of Li-chalcogen cells with unprecedented volumetric energy densities for near-future applications.