Total Specific Pore Length as a Key Feature of Carbon Support for High‐Performance Low‐Catalyst‐Loading Fuel Cells

Advanced Energy Materials, EarlyView.

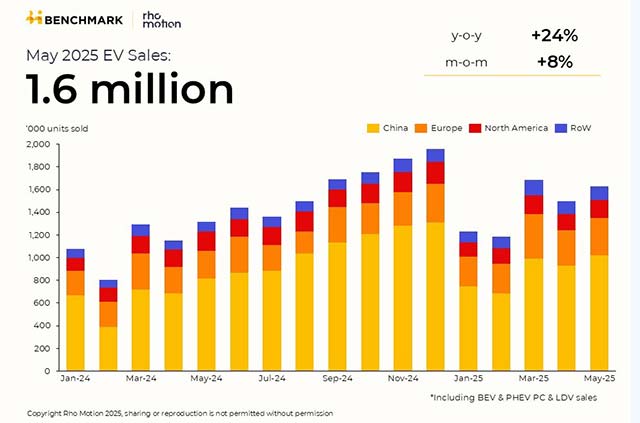

A new descriptor, total specific pore length, quantifies carbon support pore structure in fuel cells, linking it to oxygen transport and performance. Interconnected porous carbon (ICPC) with optimized pore length achieves ultralow platinum loading and top-tier power density, pushing fuel cell technology toward efficient, cost-effective frontiers.

Abstract

To simultaneously achieve high power density, stability, and low platinum group metal (PGM) loading in the proton exchange membrane fuel cells, porous carbon materials are generally used as supports to anchor the Pt-based catalysts. Despite substantial studies on improving fuel cell performance via carbon support engineering, quantitatively identifying the preferable 3D pore feature remains a challenge. Herein, electron tomography is used to obtain the nano-scale 3D structure of representative carbon supports, which allowed us to quantitatively analysis the pore structure. A descriptor “total specific pore length” is introduced, which is defined as the sum of the pore lengths divided by the volume of the carbon matrix. We find larger total specific pore length correlates with higher oxygen transport rate in the membrane electrode assembly (MEA) test. Moreover, it is demonstrated that interconnected porous carbon, which shows a large total specific pore length, enables the catalyst to deliver a state-of-the-art rated power of 17.0 kW gPGM −1, with all key features (catalyst mass activity, rated power, and stability) surpassing the target set by the U.S. Department of Energy. As a result, the PGM loading of the MEA can be reduced to an ultralow level of 0.060 mg cm− 2.