Enhancing Form Stability: Shrink‐Resistant Hydrogels Made of Interpenetrating Networks of Recombinant Spider Silk and Collagen‐I

Advanced Healthcare Materials, Volume 14, Issue 12, May 6, 2025.

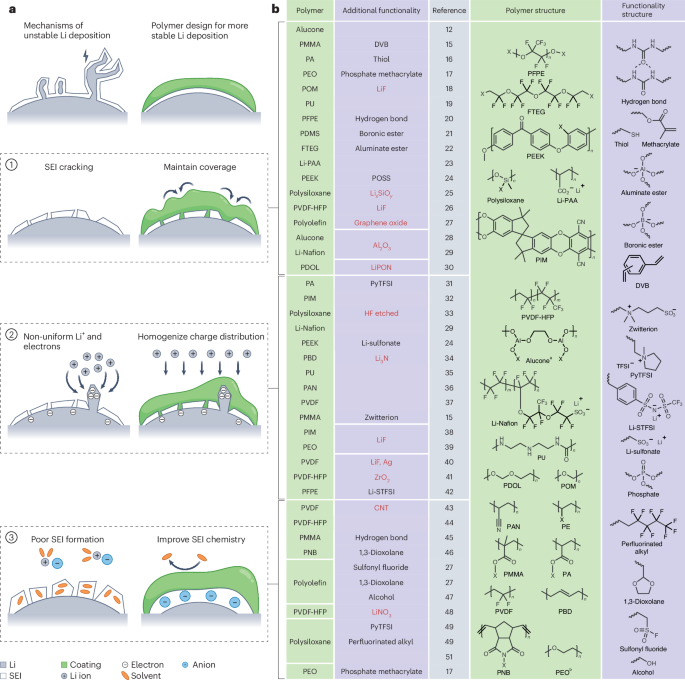

A shrinkage-resistant hydrogel is developed to confer post-fabrication shape fidelity. The hydrogel, based on recombinant spider silk protein eADF4(C16)-RGD and collagen-I, exhibits tunable mechanical properties and shrink-resistance in the presence of fibroblasts as well as muscle cells. The hydrogel is suitable for muscle engineering allowing cell differentiation, muscle function, and drug testing.

Abstract

Tissue engineering enables the production of tissues and organ-like structures as models for drug testing and mechanistical studies or functional replacements for injured tissues. Available cytocompatible materials are limited in number, suffer from insufficient mechanical properties, and cells interacting with them often cause construct shrinkage. As shape is important for function, identifying cytocompatible, shrink-resistant materials are a major aim. Here, it is shown that hydrogels made of interpenetrating networks of collagen-I and recombinant spider silk protein eADF4(C16)-RGD nanofibrils exhibit synergistic and tunable mechanical properties. Composite hydrogels allow cell adhesion and spreading and are resistant to shrinkage mediated by fibroblasts, C2C12 myoblasts, and human induced pluripotent stem cell (hiPSC)-derived cardiomyocytes. Myoblasts differentiate and fuse into myotubes, and hiPSC-cardiomyocytes can be cultured long-term, show spontaneous contractions, and remain drug responsive. Collectively, a novel composite material is developed to overcome the challenge of post-fabrication matrix shrinkage conferring high shape fidelity suitable for tissue engineering.