An Assessment of Blended Short Loop Recycled Graphite Electrodes Using X‐Ray Micro‐Computed Tomography

Advanced Energy Materials, Volume 15, Issue 20, May 27, 2025.

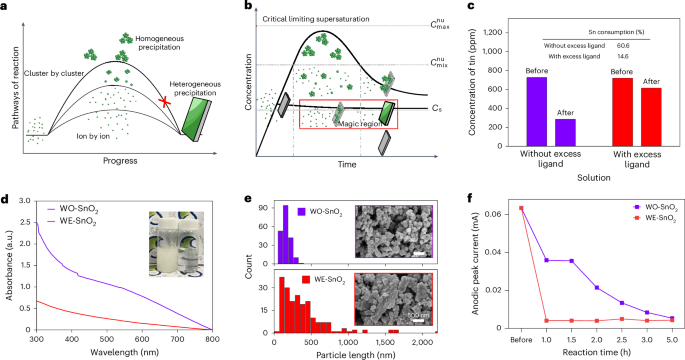

X-ray micro-computed tomography is useful for assessing structural and diffusivity changes within short-loop recycled electrode materials. Delamination via water with and without ultrasonic assistance, influences the structure of the remanufactured electrodes. Incorporating 20 wt.% of short-loop recycled graphite has a minimal effect on battery performance compared to pristine material.

Abstract

With various battery directives necessitating the composition of recycled electrode materials this study manufactures anodes containing various ratios of pristine and reclaimed graphite from end-of-life (EOL) cells. Two approaches that can be used to delaminate graphite are using ultrasonication (USD) and simple water delamination (WD). X-ray micro-computed tomography is used to characterize the graphite particles and show that particle fracturing is evident with both methods, but key structural metrics such as particle radius and diffusivity varied significantly. It is shown that blending 20% recovers material with 80% pristine graphite causes no statistically significant difference in the performance of the cells. This suggests that recycling anode materials can be achieved without significant post-processing required. For WD anode material, the spherical graphite particles are maintained, whereas USD significantly changes the morphology and produces a large amount of “needle-like” particles. Using 100% reclaimed anode material causes the performance of the cell to decrease to 279 mAh g−1 for WD material and 254 mAh g−1 for USD graphite. The use of “blended” electrodes using WD graphite and pristine material creates electrodes with a comparable Li+ flux and electrochemical performance to a pristine graphite reference of 300–315 mAh g−1.