2028 Mk9 Volkswagen Golf to use advanced Rivian software

VW design boss Andreas Mindt confirmed to Autocar that his team is working on the Mk9 Golf Electric ID Golf will use system developed as part of joint-venture with US firm Rivian The next-generation electric Volkswagen Golf due in around 2028 will be one of the first cars to benefit from the full potential of the firm’s new software system, developed in a joint venture with EV start-up Rivian. The ninth-generation car, set to be called ID Golf, is currently in development, and will be the first to be fully electric. It is set to be one of the first models to use the VW Group’s next-generation SSP electric car platform. When it launches it will be sold alongside the existing combustion-engined Golf, with production of that model moving from Germany to Mexico in 2027. Last year the Volkswagen Group invested £4.6 billion into US EV firm Rivian to form a new joint venture dedicated to developing an advanced new software architecture. Built on the system currently used in the Rivian R1T pick-up and R1S SUV, the flexible new architecture controls all the key functions of the vehicle, and allows for over-the-air updates that can even be used to adjust hardware settings. The production version of the new £17,000 ID Every1 city car concept will be the first Volkswagen model to use a version of the new Rivian-derived software platform when it launches in 2027. The switch to a software-driven vehicle architecture will help to reduce development and production costs for the price-sensitive car, but Grünitz hinted the decision was, in part, to help develop the architecture for the crucial next-gen Golf. “The ID 1 will be the very first vehicle with that architecture, and will be the frontrunner on our side for the ID Golf,” said VW technical chief Kai Grünitz. “This reduces the risk for the Golf, because we will start with lower functionality in the ID Every1 than will be necessary for the ID Golf." The new software system being developed by the Rivian-VW joint venture is termed a zonal architecture, with all the software systems consolidated onto a handful of electronic control units, rather than all running on numerous separate control units, as is the case with current vehicles. Grünitz said that will enable Volkswagen to offer different levels of functions in different types of vehicles using the same software system. “The benefit of the zonal architecture is that I can put one, two or three zones in a vehicle,” said Grünitz. “Vehicle in lower price segments will just need one zone, while a premium vehicle might need three or four, depending on functions. "I can use a dedicated System on Chip (SoC) family for each model, so for the ID 1 I can use an SoC with a lower price point and complexity. But if I take the same architecture over to the Golf I can use a different SoC that costs more money but gives additional functions - but it's still the same software. "The benefit of this new software and architecture is that it's highly flexible and highly updatable. We see it already on the road with Rivian today [which offers regular over-the-air updates and new functions]. I can offer new functions to customers even after they have bought their car without touching them. So this is really the next step." As previously reported by Autocar, the switch to the new SSP platform will mean the ID Golf uses an 800V architecture, offering substantially faster charging times and greater efficiency than current ID models. It will also offer more autonomous driving functions and gain GTI and R variants. The EV will also be one of the first to use Volkswagen's new unified battery cells, which have been designed to be fitted to around 80% of the VW Group's future models and can be used to house a range of different battery chemistries and technologies. The cells allow for a cell-to-pack design, which allows more cells to be fitted into the same space, allowing for greater capacity and efficiency. Switching to a unifed cell, which the VW Group will produce itself, will also boost economies of scale. Volkswagen has yet to confirm further details of the ID Golf, but design chief Andreas Mindt did confirm to Autocar that his team is working on the model. “I was involved in the design of the Golf Mk6 and Mk7, and right now I’m deep into the story of Golf,” he said. “I see a lot of chances for a future, and a lot of good things that can happen to it. The Golf is a special thing within Volkswagen, and you have to stay true to the Golf. It’s a brand on its own, but you can play with this. There’s so much nice content you can use – but I cannot say more now.” However, the ID Every1 concept, and the ID 2all that will arrive in production form next year, both showcase a new design language that draws deeply on Volkswagen's long heritage. As a result, it is likely that the new ID Golf will retain many of the key styling features of the existing version. ICE Golf production to continue - in Mexico The new ID Golf will be manufactured alongsi

VW design boss Andreas Mindt confirmed to Autocar that his team is working on the Mk9 GolfElectric ID Golf will use system developed as part of joint-venture with US firm Rivian

The next-generation electric Volkswagen Golf due in around 2028 will be one of the first cars to benefit from the full potential of the firm’s new software system, developed in a joint venture with EV start-up Rivian.

The ninth-generation car, set to be called ID Golf, is currently in development, and will be the first to be fully electric. It is set to be one of the first models to use the VW Group’s next-generation SSP electric car platform. When it launches it will be sold alongside the existing combustion-engined Golf, with production of that model moving from Germany to Mexico in 2027.

Last year the Volkswagen Group invested £4.6 billion into US EV firm Rivian to form a new joint venture dedicated to developing an advanced new software architecture. Built on the system currently used in the Rivian R1T pick-up and R1S SUV, the flexible new architecture controls all the key functions of the vehicle, and allows for over-the-air updates that can even be used to adjust hardware settings.

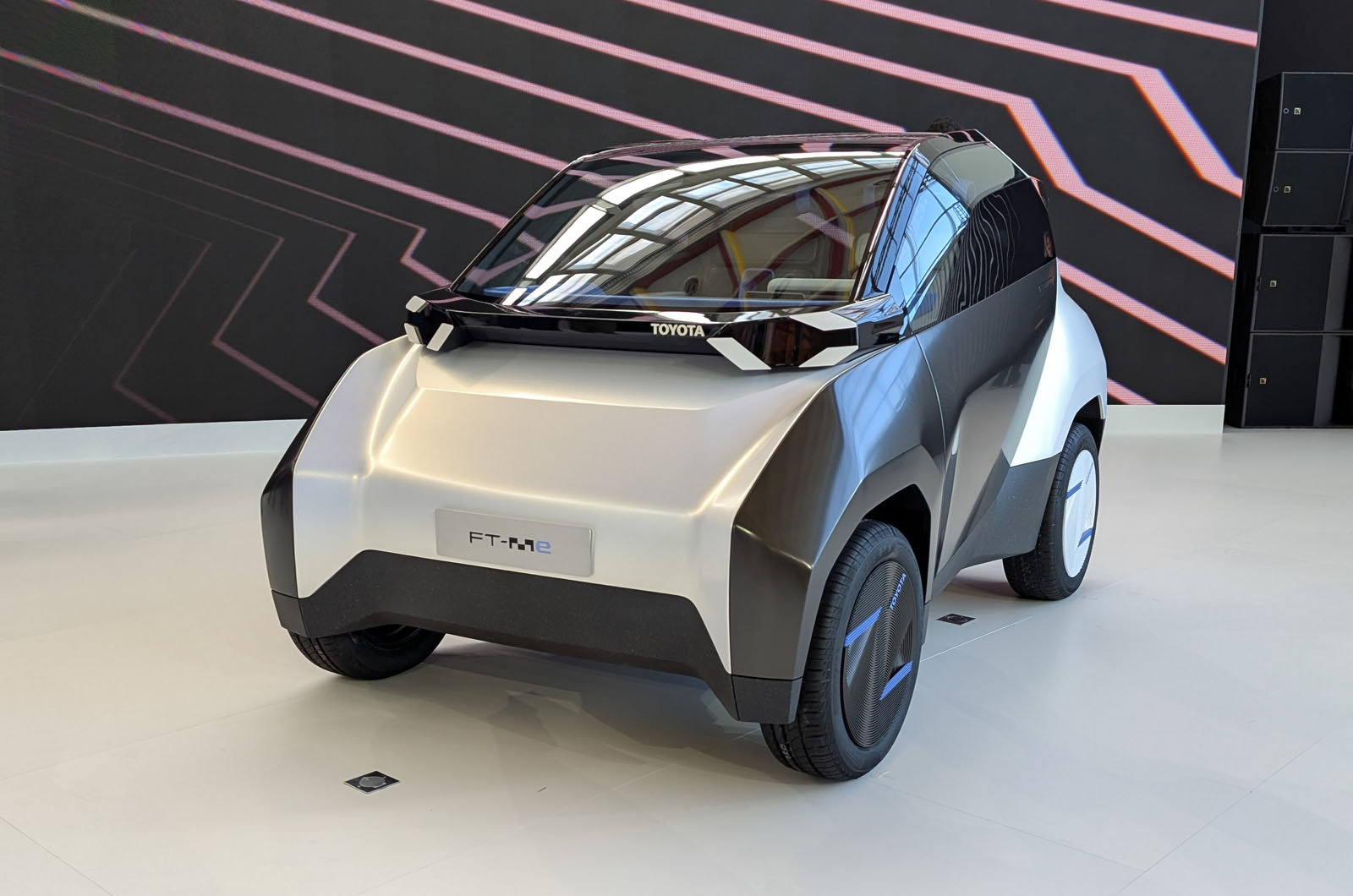

The production version of the new £17,000 ID Every1 city car concept will be the first Volkswagen model to use a version of the new Rivian-derived software platform when it launches in 2027. The switch to a software-driven vehicle architecture will help to reduce development and production costs for the price-sensitive car, but Grünitz hinted the decision was, in part, to help develop the architecture for the crucial next-gen Golf.

“The ID 1 will be the very first vehicle with that architecture, and will be the frontrunner on our side for the ID Golf,” said VW technical chief Kai Grünitz. “This reduces the risk for the Golf, because we will start with lower functionality in the ID Every1 than will be necessary for the ID Golf."

![]()

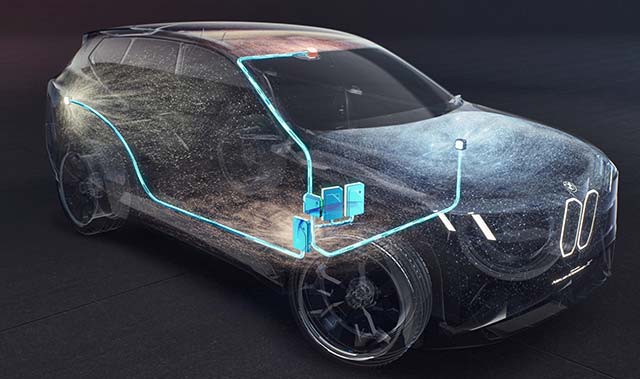

The new software system being developed by the Rivian-VW joint venture is termed a zonal architecture, with all the software systems consolidated onto a handful of electronic control units, rather than all running on numerous separate control units, as is the case with current vehicles. Grünitz said that will enable Volkswagen to offer different levels of functions in different types of vehicles using the same software system.

“The benefit of the zonal architecture is that I can put one, two or three zones in a vehicle,” said Grünitz. “Vehicle in lower price segments will just need one zone, while a premium vehicle might need three or four, depending on functions.

"I can use a dedicated System on Chip (SoC) family for each model, so for the ID 1 I can use an SoC with a lower price point and complexity. But if I take the same architecture over to the Golf I can use a different SoC that costs more money but gives additional functions - but it's still the same software.

"The benefit of this new software and architecture is that it's highly flexible and highly updatable. We see it already on the road with Rivian today [which offers regular over-the-air updates and new functions]. I can offer new functions to customers even after they have bought their car without touching them. So this is really the next step."

As previously reported by Autocar, the switch to the new SSP platform will mean the ID Golf uses an 800V architecture, offering substantially faster charging times and greater efficiency than current ID models. It will also offer more autonomous driving functions and gain GTI and R variants.

The EV will also be one of the first to use Volkswagen's new unified battery cells, which have been designed to be fitted to around 80% of the VW Group's future models and can be used to house a range of different battery chemistries and technologies. The cells allow for a cell-to-pack design, which allows more cells to be fitted into the same space, allowing for greater capacity and efficiency. Switching to a unifed cell, which the VW Group will produce itself, will also boost economies of scale.

Volkswagen has yet to confirm further details of the ID Golf, but design chief Andreas Mindt did confirm to Autocar that his team is working on the model.

“I was involved in the design of the Golf Mk6 and Mk7, and right now I’m deep into the story of Golf,” he said. “I see a lot of chances for a future, and a lot of good things that can happen to it. The Golf is a special thing within Volkswagen, and you have to stay true to the Golf. It’s a brand on its own, but you can play with this. There’s so much nice content you can use – but I cannot say more now.”

However, the ID Every1 concept, and the ID 2all that will arrive in production form next year, both showcase a new design language that draws deeply on Volkswagen's long heritage. As a result, it is likely that the new ID Golf will retain many of the key styling features of the existing version.

ICE Golf production to continue - in Mexico

The new ID Golf will be manufactured alongside a closely related model on the SSP platform at Volkswagen's main factory in Wolfsburg. As part of a major cost-reduction plan that will involve significant job cuts, the VW Group is revamping much of its production plans in Germany. That will include production of the existing combustion-engined Golf moving from Wolfsburg to VW's plant in Puebla, Mexico.

Even if it will be replaced by a new electric version that will mark a significant transition, because combustion-engined Golfs have been produced in Wolfsburg since the first generation model launched in 1974.

Notably, VW has hinted that the sale of existing combustion-engined and hybrid models could be extended for as long as there is customer demand. The Golf's predecessor, the Beetle, was also produced in Mexico with the final version coming off production lines there in 2003, nearly 30 years after production at Wolfsburg was discontinued. Puebla currently builds the Jetta, Tiguan LWB and Taos models.

Speaking during the VW Group's annual media conference, group boss Oliver Blume said that, while EVs remains the company's ultimate focus, the speed of transition would "depend on global regions". He added the group had "an entrepreneurial obligation to have a broad spread [of powertrains] that offered higher robustness", and while he predicted Europe could be EV-only by 2035 that there was a need for "flexibility".

As part of the factory reshuffle, production of the ID 3 and Cupra Born Evs will also move to Wolfsburg, which will switch to two production lines rather than the four currently in use.