Novel Fe‐Modulating Raney‐Ni Electrodes toward High‐Efficient and Durable AEM Water Electrolyzer

Advanced Energy Materials, EarlyView.

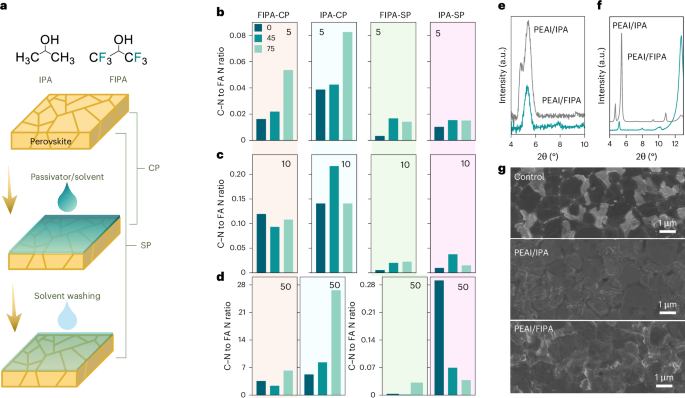

Plasma spray (APS) is used to fabricate Fe-modulated Raney-Ni bifunctional electrodes for AEMWE. The resulting NFA-CA exhibits distinct core–shell NiFe-NiFe hydroxides, enabling 2 A cm⁻2 at 1.79 V—surpassing the U.S. Department of Energy's target for AWE systems—and demonstrates excellent durability with 1000 hours of stable operation at 1 A cm⁻2.

Abstract

Anion exchange membrane (AEM) water electrolysis holds promise for green hydrogen production. One of the main challenges is the preparation of highly efficient electrodes with scalable techniques. Herein, a novel Fe-modulating Raney-Ni electrode (NFA-CA) is developed through atmospheric plasma spraying and chemical etching techniques. The resulting electrode demonstrates high bifunctional catalytic activities with low overpotentials and Tafel slopes (HER: 27 mV at 10 mA cm−2, 20 mV dec−1; OER: 169 mV at 10 mA cm−2, 49 mV dec−1), competing for precious-metal catalysts and leading transition-metal-based compounds reported in the literature. Moreover, the corresponding AEM electrolyzer only requires 1.56 V to drive 1 A cm−2 and exceptional durability for 1000 h. Moreover, the AEM cell can reach 2 A cm−2 at 1.79 V, exceeding the United States Department of Energy target for AWE systems (2 A cm−2 at 1.80 V). The highly efficient and durable performance is attributed to the NiFe nanocrystals (core)-NiFe hydroxide (shell) nanostructures created by the treatment. This structure not only facilitates superior electrocatalytic properties but it is also maintained after 1000 h of continuous operation. It is consider that the present approach can offer an attractive route for scalable fabrication of NiFe-based electrodes for industrial AEM water electrolyzers.