Non‐Halogenated Solvent‐Processed Organic Solar Cells with Efficiencies Exceeding 20.0% and 110 cm2 Modules Exceeding 13% Enabled by Film‐Forming Dynamics Engineering

Advanced Energy Materials, EarlyView.

This work integrates crystallization dynamics and computational fluid dynamics simulations to control the morphology of film during the fabrication of organic solar cells using non-halogenated solvents. Thanks to controlled phase separation and optimized nanostructure, a record efficiency of 20.3% is achieved while large-area modules (100 cm2) deliver 13.1% efficiency with a certified value of 12.7%, demonstrating the technology's excellent scalability and environmental compatibility.

Abstract

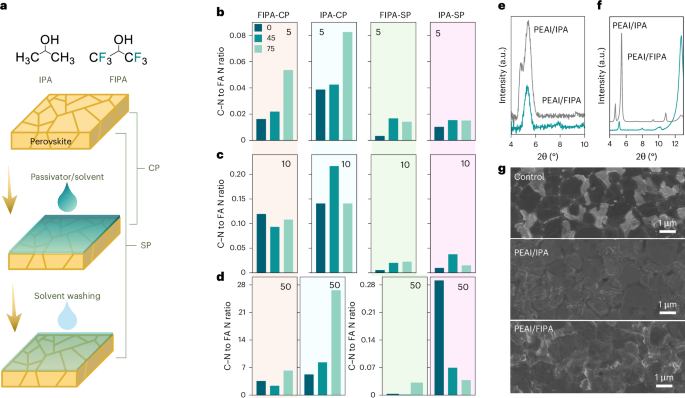

The efficiency of small-area organic solar cells (OSCs) has now exceeded 20%, while mini-modules have achieved efficiencies of over 17%. However, the performance of large area modules over 100 cm2 still lags behind, largely due to the limitation of precisely controlling the film formation dynamics to achieve optimal crystallinity and nanomorphology. In this study, phase separation and polymer rheology are synergistically investigated during film formation. Using computational fluid dynamics (CFD) simulations and theoretical calculations, the film formation dynamics are thoroughly investigated in large-area modules and propose a heat-enhanced fast morphological evolution strategy (HF). This method mitigates excessive phase separation during large-area film deposition, reduces non-radiative recombination, and enhances charge carrier transport. Devices based on PM1:L8-BO:BTP-eC9 processed using a non-halogenated high-boiling point solvent exhibit a power conversion efficiency (PCE) of 20.3%, with the corresponding 110 cm2 (active area of 100 cm2) module achieving an efficiency of 13.1% (certified PCE of 12.7%). Finally, the potential applications of organic solar cell modules in environmental protection and medical fields are demonstrated.