Efficient Omnichannel Processing Increases Capacity of The Foschini Group (TFG) in South Africa

TFG has selected FORTNA as its strategic partner to optimise omnichannel fulfillment through intelligent automation and software — setting new benchmarks for efficiency, scalability, and service levels in South Africa. Reduced transport costs strengthened omnichannel and e-commerce capacities, and accelerated responsiveness: ambitious goals that are being achieved by The Foschini Group (TFG) with the new [...] The post Efficient Omnichannel Processing Increases Capacity of The Foschini Group (TFG) in South Africa first appeared on Warehouse & Logistics News.

Reduced transport costs strengthened omnichannel and e-commerce capacities, and accelerated responsiveness: ambitious goals that are being achieved by The Foschini Group (TFG) with the new state-of-the-art Riverfields Distribution Centre in Gauteng, South Africa. With the automation of picking processes, TFG has set another milestone in its strategic expansion plan. As an integrator and software supplier, FORTNA, with whom the South African retailer has been successfully collaborating with for years, is responsible for the successful design and implementation of advanced automation technologies and intelligent software to enhance e-commerce performance and optimise inventory management in this project.

Founded in 1924, The Foschini Group (TFG Limited), headquartered in Cape Town, South Africa, specializes in the omnichannel distribution of lifestyle and apparel sectors across 37 retail brands. TFG has significantly expanded its portfolio with well-known premium brands through strategic acquisitions both locally and abroad in 27 countries across 5 continents. A key focus for the Group is rapid response throughout their supply chain: their top priority is fast, efficient transport to both stores and e-commerce to enable an optimal customer shopping experience.

Centralised Fulfillment – The Effects

To ensure optimal availability of their product range at their point of sale, TFG operates several distribution centres (DCs) across South Africa. One of them is the state-of-the-art Riverfields DC, which was commissioned in September 2024. Riverfields DC is part of a multi-phase supply chain optimisation initiative that targets the continued increase of the site’s capacity to centralise the stock for both store and e-commerce fulfillment. Riverfields enables the strategy to consolidate 13 smaller distribution centers to 7 to meet continuously growing demands for speed and efficiency.

“We needed to significantly strengthen our central capabilities in fulfillment and distribution closer to our biggest market in Gauteng and above all, optimise operations by implementing consolidated processing,” explains Michael Rhategan, Head of Logistics at TFG. “Our new Riverfields Distribution Centre successfully went into operation with the support of FORTNA in 2024. It is the heart of our centralised omnichannel strategy and key to significantly improving on multiple levels.”

With an impressive footprint of 75,000 sqm, the integration of advanced software and state-of-the-art technologies allows for automated order consolidation of over 22 brands. This increases the centralised processing of all e-commerce orders targeting 70% central fulfillment. Rapid demand response capabilities enhance the availability of individual clothing sizes in the stores. In addition, order fulfillment costs are significantly reduced through a reduction in parcels per order which also improves customer experience with fewer “doorbell” rings. Centralisation of both store fulfillment and e-commerce further adds opportunities through shared transport networks for both click-and-collect deliveries and home deliveries. The new supply chain and intralogistics design supports the development of resilient, flexible scenarios for supplying retail in response to changing requirements and thus facilitates all strategic sales initiatives.

Technology and Processes – The Highlights

“FORTNA’s design approach is strictly data-based and ideally tailored to the customer’s requirements. For TFG, we took into account various complex design parameters that impact the entire intralogistics and supply chain ecosystem for sustainable, effective results. Our focus is translating the explosive increase in customer orders into high-performing operations,” explains Fayyaaz Akoob, Senior Project Manager at FORTNA. “To more efficiently handle an average of 450,000 shipments per week, we introduced automation in the goods receipt, picking, and also in dispatch processes. FORTNA WES , our warehouse execution system software, now dynamically assigns tasks, balances loads and enables an optimal utilisation of available workforce and technical resources. It is the central platform that allows TFG to monitor and control all processes in real-time, empowering them to respond rapidly to changing requirements and unexpected events.”

, our warehouse execution system software, now dynamically assigns tasks, balances loads and enables an optimal utilisation of available workforce and technical resources. It is the central platform that allows TFG to monitor and control all processes in real-time, empowering them to respond rapidly to changing requirements and unexpected events.”

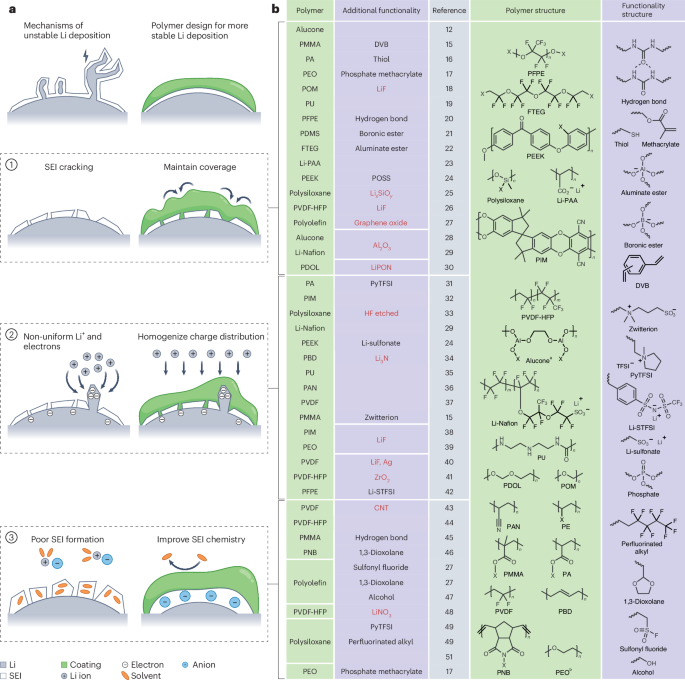

In the goods receipt process, as well as in storage, retrieval, and picking, TFG uses RFID tunnels for automated, precise identification of items, which in turn allows significantly accelerated, more accurate inventory management. With the new demand-driven retail supply, global best practices of the fashion supply chain could be adopted: a demand-driven “pull strategy,” which is very responsive in allocating inventory to current demand, replaces the previously applied forecast-driven “push model.” The exact mapping of inventory in the stores and current demand reduces the need to discount assortment in the stores to relieve the limited storage capacity.

In dispatch, orders are differentiated by order type, order volume, and shipping destination to ensure maximum efficiency and accuracy: for larger orders, items are sorted according to the “put-to-store” model and directly distributed to the respective points of sale. Smaller B2C orders are manually picked in a new 4-story shelving system with 190,000 picking bays.

To further increase efficiency, especially during promotional periods and seasonal peaks, a put-wall system was implemented to support batch picking and the consolidation of multi-order processing. “The advantages of this system are its modularity and scalability,” explains Fayyaaz Akoob. “It can be flexibly adapted to different product sizes and order profiles without much effort.”

Success and Future Outlook

“Riverfields DC has enabled additional marketplace opportunities for our Bash division. The operational requirements to support this sales channel have already been taken into consideration within the design of the expansion of the distribution centre. All initiatives that we have successfully implemented, supported by the strong partnership with FORTNA, directly contribute to our goal of offering our customers a seamless, unique omnichannel customer experience across all platforms,” says Michael Rhategan. “This positions us well to maintain and further expand our competitive advantage in the future.”